Implementation of “Simulated Use and Determination of the Changes in Properties-Seat cushions” Standard, It’s use and implications

Author Name(s) Evan Call MS CSM-NRM1, Kara Koplin2 Dr. Barb Crane PhD, PT, ATP/SMS3

Author Affiliation(s) 1Weber State University and RESNA WRS Standards Committee, 2 ROHO, and RESNA WRS Standards Committee 3University of Hartford and RESNA WRS Standards CommitteeIntroduction

The introduction of a RESNA standard for the simulation of the effects of use on wheelchair cushions and the impact that simulated use has on cushion performance has created some interest in potential application of the standard. One of the areas of application could be the standardization of the wheelchair cushion code verification process where the aging portion of the required test process currently has no specific requirement. This standard is based on ISO 16840-6.

The Standard Process

The standard calls for a four-step process. First; the manufacturer is to identify the intended use of the cushion, which defines the simulated use “aging” that is, to be performed. Second; tests to characterize the pre-aging performance of the cushion are selected from the available list and performed. Third: the cushion is then aged based on the listed aging requirements, and Fourth: following the aging process, the characterization tests performed again. The test results are reported as the change in cushion characterization test results observed between pre and post aging

The strength of this standard test concept is that even though there are 10 different cushion categories identified in the standard, see the table below, provision is made for a manufacturer to define their own intended use and thus the required aging processes. In addition a manufacturer can also identify the characterization tests that are appropriate to some unique feature of their cushion. While customization is made available in the standard, it is clear that the testing required in the 10 listed categories is more than is typically performed by companies submitting for code verification today.

cushion Categories and required tests

Required Aging Exposures |

26,25,22,29,23,27,26,30,29,28 |

| The Following Are Examples of Tests Based on Manufacturer’s Recommended Use | Aging Exposures by Clause (to be performed in sequence) |

| Intermittent use without incontinence | 26,25,22,29,23,26,31,28 |

| Wet environment (shower / toileting) | 26,25,22,23,27,26,30,28,25,22,28 |

| Perspiration (sport or hot environment) | 26,25,22,29,23,27,26,30,31,28 |

| Incontinence (faecal and/or urinary) | 26,25,22,29,23,27,29,26,29,30,29,23,26,29,30,29,28 |

| Heavy use (including outdoor) | 29, 26,25,22,29,23,27,26,30,31,28,24, 29 |

| Extremes of climate: HOT | 26,25,22,29,23,26,29,28,25,22,28 |

| Extremes of climate: COLD | 26,25,22,29,23,27,26,30,29,24 |

| Utility (multiple environments during normal daily use ) | 26,25,22,29,23,27,26,30,29,31,28,24 |

| Robust utility (incontinence with heavy use, washing, and disinfection) | 26,25,22,29,23,27,26,30,29,23,27,26,30,29,31,28,24 |

| Hybrid (minimum plus special case) | Minimum plus MFG special case |

The Characterization tests identified in the standard for pre and post-aging characterization of the cushion is found in Table 2 below.

| Test Name | Clause |

|---|---|

| Envelopment | 9 |

| Column buckling | 10 |

| Heat and humidity | 11 |

| Heated indenter compression set | 12 |

| Impact damping under normal conditions | 13 |

| Interface pressure measurement (pressure mapping) | 14 |

| Lateral stiffness | 15 |

| Leak | 16 |

| Load deflection and hysteresis | 17 |

| Loaded contour depth and overload deflection | 18 |

| Sliding resistance | 19 |

| 10% Force deflection | 20 |

The key to the tests defined in table one is found in table 3 below.

| Test Description | Test No. |

|---|---|

| Temperature accelerated Aging | 22 |

| Bacterial Soiling | 23 |

| Cold exposure | 24 |

| Cyclic loading at elevated temperature | 25 |

| Disinfection | 26 |

| Fecal Soiling with Cyclic loading | 27 |

| Heat and Humidity | 28 |

| Laundering | 29 |

| Urinary Soiling with Cyclic Loading | 30 |

| UV and Ozone Exposure | 31 |

Test Performance and Results

Example of Test Process

A series of cushions were selected that fit the “Robust Utility” Category. The Characterization tests that were selected were; Hysteresis, Column Buckling, Loaded Contour, and Envelopment. Following testing, the aging process was performed as defined.

During the aging process, one of the cushion that contained an air bladder, developed a leak. The cushion was repaired and returned to the test. When the repair began to leak, it was determined that a replacement cushion would be tested because the process of repairing the cushion had inadvertently compromised the cushion so that continuing the test would be an unreasonably aggressive challenge.

Aging Steps Applied

The aging processes that were used to challenge the cushions in this test include those descried in Table 1 under Robust Utility. Note that some of the aging steps are repeated multiple times to simulate actual use. For example the disinfection process is carried out three times at different points in the aging process. In addition Fecal soiling is also repeated two times in the process. This is intended to reflect actual events in the life of the cushion.

Example Results

Pre and Post Aging Data

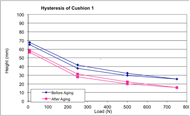

Figure 1 Hysteresis of Sample Cushion 1

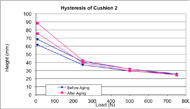

Figure 1 Hysteresis of Sample Cushion 1 Figure 2 Hysteresis of Sample Cushion 2

Figure 2 Hysteresis of Sample Cushion 2

It is important to note that multiple cushion tested in this process demonstrate different performance characteristics in both the pre and post data. See the different levels of performance as well as the different response to aging shown in Figure 2 of Sample Cushion 2.

Additional results for each test are available and will be presented as time allows.

References

- ISO 16840-2 Wheelchair Seating – Section 2: Determination of Physical and Mechanical Characteristics of Devices Intended to Manage Tissue Integrity – Seat Cushions.

- ISO/WD 16840-6 :2013 Wheelchair Seating –Part 6 Simulated use and determination of the changes in properties - Seat cushions

- ISO 554:1976E Standard Atmospheres for Conditioning and/or testing – Specifications

- ISO 9073-8:1995 Textiles. Test Methods for Nonwovens. Determination of Liquid Strike-Though Time (Simulated Urine)

- RESNA SS-1:2011 Section 3 – Standard Protocol for Measuring Heat and Water Vapor Dissipation Characteristics of Full Body Support Surfaces – Body Analog Method

- AAMI TIR 12 - 1994 Designing, Testing, and Labeling Reusable Medical Devices for Reprocessing in Healthcare Facilities: A Guide for Medical Device Manufacturers.

Acknowledgements

This testing Process was kindly funded by Roho in the interest of evaluating the proposed test method.