A Drive system to add standing mobility to a manual standing wheelchair

Eric Nickel1, Andrew Hansen1,2, Jon Pearlman3,4, Gary Goldish1,2

1Minneapolis VA Health Care System, Minneapolis, MN, 2Department of Physical Medicine and Rehabilitation, University of Minnesota, Minneapolis, MN, 3Department of Rehabilitation Science and Technology, University of Pittsburgh, Pittsburgh, PA, 4VA Pittsburgh Health Care System

ABSTRACT

A prototype manual standing wheelchair with standing mobility was developed with feedback from a User Advisory Panel of four wheelchair users. The panel members reported that mobility during standing was very important or extremely important to them. Stability testing demonstrated the center of pressure under the chair remained well within the base of support during directional leaning activities. The panel members liked the stability and mobility of the prototype and provided feedback for future refinements of the design. For example, reducing the overall width (width from hand rim to hand rim) and weight could make this system more functional for users.

BACKGROUND

Persons with spinal cord injury or disease (SCI/D) are prone to sitting surface pressure wounds due to impaired mobility, sensation, autonomic control of skin blood flow and moisture related issues (Byrne & Salzberg, 1996; and Salzberg, et al., 1998). Pressure relieving wheelchair cushions are beneficial but even relatively low pressures sustained for long periods can result in skin breakdown (Kosiak, 1961).

There is a growing consensus that regular standing is an effective method for reducing risk of sitting surface pressure ulcers. Current devices that aid persons with SCI/D to stand at home and in the community generally come in three forms, each with their own advantages and disadvantages.

Standing frames have the advantage of low cost because they are exclusively designed for standing. Some standing frames offer limited propulsion in a standing position by means of small hand rims connected through a belt to drive wheels, but these frames are bulky and inefficient to propel. In addition, standing frames are not mobile while sitting.

Commercially available manual standing wheelchairs are immobile when standing. These are an improvement over a standing frame because they at least have the ability for mobility while seated, but these devices have limited appeal to some users due to the lack of mobility while standing.

Some commercially available power wheelchairs offer mobility when standing. However, power wheelchairs are expensive, bulky, prone to mechanical failure and difficult to transport. Such devices are usually not covered by third party payers if the patient has the upper extremity strength to propel a manual chair.

The RESNA Position on the Application of Wheelchair Standing Devices (Arva, et al. 2009) states that they are often “medically necessary” and that “an integrated wheelchair standing system may allow for moving about while in a standing position so that the medical benefits … can be reaped while an individual carries out their daily routine. This may also improve compliance with the system.”

Some work has been done to develop manual standing wheelchairs that are mobile in the standing position (Churchward, 1985; Kuiken, 2005). Kuiken’s design uses two different propulsion methods for sitting and standing operation (hand rims and lever drives, respectively), which may complicate its acceptance and use. Churchward’s design uses hand rims for both sitting and standing propulsion, but is bulky and has a complicated system for transitions between sitting and standing.

PURPOSE

The purpose of this study was to develop a prototype manual wheelchair with standing mobility to demonstrate proof-of-principle for future commercialization.

METHOD

Prototype Design

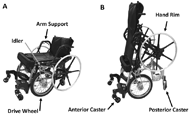

Figure 1: Pictures of the new drive system retrofitted to a commercially available manual standing wheelchair in both seated (A) and standing (B) configurations. Key elements of the drive system are labeled.

Figure 1: Pictures of the new drive system retrofitted to a commercially available manual standing wheelchair in both seated (A) and standing (B) configurations. Key elements of the drive system are labeled.

The drive wheels are 16-inch diameter and mounted to the anterior portion of the wheelchair frame (Figure 1), resulting in a “front-wheel drive” chair when seated.

Anterior casters mounted to the foot support (Figure 1) extend the base of support when standing. The foot support descends when the user stands up, bringing the anterior casters into contact with the ground and making the chair mid-wheel drive when standing. When seated, the casters are approximately two inches above the ground providing the clearance needed for propulsion over short obstacles, such as door thresholds and curb cuts.

The chain drive transfers torque from the hub of the hand rims, which are mounted on the arm supports of the wheelchair, to the drive wheels, which are mounted on the frame of the wheelchair (Figure 1). Sprockets can be changed by the wheelchair clinician to alter the propulsion gear ratio. An idler sprocket mounted at the pivot between the arm support and the frame acts as an intermediate coupling between the two stages of the drive. The sprockets are stainless steel bicycle sprockets and the chain is standard bicycle chain.

The hand rims are mounted to the arm support of the wheelchair via a frame of steel tubing clamped onto the bottom tube of the arm supports (Figure 1). The frame allows the hand rims to be mounted in the same approximate location as the original wheel/hand rim axis or other locations, as desired. This could also permit hand rim locations not possible with conventional manual wheelchairs. Furthermore, as the arm supports rotate up for standing, the hand rims follow, maintaining accessibility for the user when standing.

The gear ratio of the drive system is designed such that one revolution of the hand rims would result in a travel distance similar to that of the original wheelchair.

Human Testing

An advisory panel consisting of four persons with spinal cord injuries provided feedback on the prototype design within an IRB-approved study. This User Advisory Panel (UAP) was composed of persons with at least 20 years since injury and injury levels of C7-T12. After providing informed consent, the UAP reviewed the proposed design options and provided feedback regarding the options and features. The UAP met again after the prototype was fabricated to observe a demonstration of the prototype and had an opportunity to ask questions. The panel members were asked to complete a short questionnaire.

One panel member who is active in a standing program and has a T5-6 injury level was invited to try the prototype. The subject was briefly trained on some of the key features and was then given an opportunity to explore the prototype on his own.

Stability Analysis

We placed the prototype on an instrumented treadmill from Bertec and calculated the center of pressure under the wheels as a nondisabled person (86 kg, 178 cm tall) leaned forward and to the sides in both seated and standing positions. Reflective markers on the caster stems and drive wheel axles were tracked by motion analysis cameras from Qualisys AB and allowed us to locate the center of pressure relative to the wheelchair base of support.

RESULTS

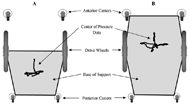

Figure 2: Static stability analysis performed on the prototype during leaning tasks in the seated (A) and standing (B) positions. Center of pressure data are overlaid on diagrams of the bases of support.

Figure 2: Static stability analysis performed on the prototype during leaning tasks in the seated (A) and standing (B) positions. Center of pressure data are overlaid on diagrams of the bases of support.

When asked how adding standing mobility to a manual standing wheelchair would affect the chair’s utility, one panel member felt it would be similarly useful, one panel member felt it would be somewhat more useful and two panel members felt it would be much more useful. No panel members felt it would be somewhat less or much less useful.

In addition to the closed response items, several open response items were included on the questionnaire. The panel members felt the standing feature would be used for activities of daily living such as cooking, cleaning, and reaching high shelves, and social activities such as greeting visitors and playing catch with children. Some of the features of the prototype the panel liked were the stability, tight turning radius, and quiet operation. Some aspects of the prototype the panel did not like were the width of the chair (hand rim to hand rim distance), weight of the arm supports with the hand rims mounted to them, and the exposed idler sprocket. The panel also felt that the total width and weight of the prototype would make transport of the chair challenging for users.

When seated the prototype is unable to perform wheelies. None of the panel members appeared to be concerned by the inability to perform wheelies when asked.

One panel member was invited to try the prototype. He felt the maneuverability of the prototype in the standing position was much better than his mobile standing frame and he liked the prototype more after trying it.

The stability analysis showed that the center of pressure under the chair remained well within the base of support during both seated and standing leaning (Figures 6 and 7) on level surfaces. During seated leaning, the ground contact point of the drive wheels mark the forward extent of the base of support whereas the anterior casters are in contact with the ground and extend the anterior base of support when standing.

DISCUSSION

The feedback from the UAP indicated strong support for mobility during standing for persons with SCI/D. The panel members were very engaged with the development team and their questions, comments, and feedback provided valuable insight into the needs of the potential user population and aspects of the present prototype that could be improved in future versions.

Key recommendations from the UAP were:

- Reduce the width between hand rims

- Reduce the weight of the rotating arm supports (including the hand rim assemblies and drive components)

- Cover the idler sprocket for safer transfers

- Strengthen the hand rim structure to support users performing wheelchair push-ups

The UAP recommended supporting wheelchair push-ups, although other pressure relieving maneuvers such as standing or leaning may be more practical as recent studies suggest 2-3 minutes may be needed for full normalization of skin blood flow (Coggrave & Rose, 2003).

The static stability analysis demonstrated excellent stability on level surfaces during both seated and standing positions. The center of pressure during seated use is approximately equidistant between the drive wheel contact line and the caster contact line, indicating approximately equal load distribution. Ideally the drive wheels would support the greater portion of the load to provide superior traction. The stability analysis does not address dynamic situations, such as might be encountered when propelling over a short obstacle or attempting to stop when propelling down a slope. Further testing to evaluate the stability under dynamic conditions or on sloped surfaces is needed, although the system is not intended for use on slopes when in the standing position.

CONCLUSION

A standing manual wheelchair that is mobile in the standing position could be a significant physical and psychological benefit for users with SCI/D. Further refinements are necessary to optimize the function, the strength, and the durability prior to field-based human subject testing of the manual standing wheelchair with standing mobility.

Use of a manual standing wheelchair with standing mobility may provide persons with SCI/D the physical and psychological health benefits of standing through the natural activities of daily life and additionally improve access to standing-height community environments, social activities, and employment opportunities. In the future, perhaps the standard of care may be a standing manual wheelchair with standing mobility for all persons able to propel a manual wheelchair.

REFERENCES

Arva, J., Paleg, G., Lange, M., Lieberman, J., Schmeler, M., Dicianno, B., Babinec, M., & Rosen, L. (2009). RESNA Position on the Application of Wheelchair Standing Devices. Assist Technol, 21(3):161–168.

Byrne, D. W. & Salzberg, C. A. (1996). Major risk factors for pressure ulcers in the spinal cord disabled: a literature review. Spinal Cord, 34(5):255-63. Review.

Churchward, R. (1985). The development of a standing wheelchair. Applied Ergonomics. 16(1):55-62.

Coggrave, M. J. 1 & Rose, L. S. (2003). A specialist seating assessment clinic: changing pressure relief practice. Spinal Cord. 41(12):692-5.

Kosiak, M. (1961). Etiology of decubitus ulcers. Archives of Physical Medicine and Rehabilitation 196142, 19-29.

Kuiken, T. (2005). Manually operable standing wheelchair. US Patent No. 6,976,698. Issued December 20, 2005.

Salzberg, C. A., Byrne, D. W., Cayten, C. G., Kabir, R., van Niewerburgh, P., Viehbeck, M., Long, H. & Jones, E.C. (1998). Predicting and preventing pressure ulcers in adults with paralysis. Adv Wound Care. 11(5):237-46.

ACKNOWLEDGEMENT

The authors would like to thank Steve Morin for his efforts in fabricating and assembling the prototype. The research reported here was supported by the Paralyzed Veterans of America grant no. 2012PVA000RES0000075260 and the Department of Veterans Affairs.