A SWITCH ACTIVATED PAGE TURNING DEVICE FOR PEOPLE WITH DISABILITIES TO INCREASE INDEPENDENT INTERACTION WITH PRINTED MATERIALS

Abstract

People who have limited or no finger, hand, or arm dexterity often find it difficult to turn pages and interact with the world of knowledge contained in printed materials. Many of these people, however, can activate machines using an electric switch, which allows for more independence in their daily lives. Assistive page turners are available commercially, but for many school systems and private families the cost of these systems is prohibitive. A low-cost page turning device has been designed, allowing a user to turn a page of printed matter by simply touching a switch with their head, hand, or other body part. This device expands the horizon of independence for people with disabilities who enjoy interacting with books and other printed media.

BACKGROUND

The Team Of Page turners (TOPs) design group was formed in response to a focused customer need at Rosedale School in Austin, Texas. Rosedale students typically have multiple, profound disabilities and most are not able to interact independently with printed materials. Rosedale presented the need for a switch activated page turning machine as a means to provide increased independence to the students. This will greatly enhance their quality of life.

At Rosedale the students interact with printed media in the classroom and in weekly library periods. Rosedale purchased a commercial page turning machine several years ago, but the machine is not used because, as the teachers describe it, "it is too bulky, too heavy, and it just doesn't work". Rosedale is reluctant to purchase another commercial page turner for these reasons, and also because most comparable commercial systems retail for $1,000 to $3,000 (1). The method currently used is for the teacher to hold the book and turn the pages as the student or class progresses through the book. Our goal is to design a device for less than $300 that will allow a student to turn pages using only the common momentary input switches widely used at Rosedale. While the device is designed to meet this goal, a more general customer base of people with similar disabilities was considered throughout the design process.

LITERATURE REVIEW

Throughout the initial phases of design and development our team conducted extensive market research on commercial page turning machines, many of which are no longer in production (1). In addition, we researched current and expired patents and patent references pertaining to page turning machines, devices, and mechanisms (2). Our market survey confirmed that commercial page turners are expensive to purchase, as much as $3,200, as previously noted.

PROBLEM STATEMENT

Over 80% of the Rosedale students lack the muscular control needed to turn a page. Therefore, the device needs to be fully automated and switch activated, requiring minimal setup. The device will be used in a group setting as well as individually. Unlike the previous page turner at Rosedale, the design needs to be compact, lightweight, and consistent at turning pages. The customer also identified portability and ease of storage as key factors in the design. Many teachers expressed that a desirable feature would be an optional audio or visual sensory feedback and reinforcement system whereby a sound will play or light will flash when the page is turned. Finally, the device needs to be affordable (less than $300), and safe to set up and operate.

DESIGN DEVELOPMENT

Our team used the systematic, detailed product design and development methodology developed by Otto and Wood (3). To define the problem, our team conducted an extensive Customer Needs Analysis (CNA). The CNA identified that there was no need for the Rosedale device to turn pages in reverse. Reverse turning, however, would likely need to be addressed for wider applications of people without cognitive or learning disabilities.

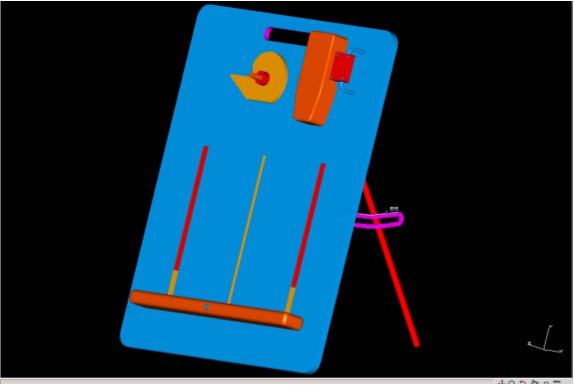

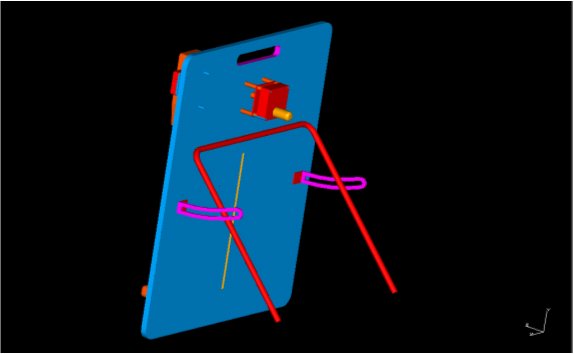

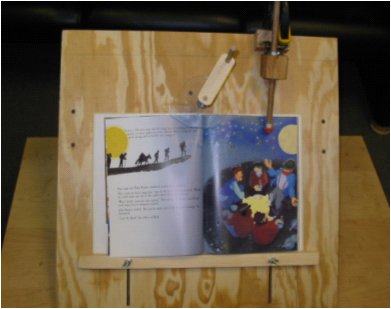

We used many methods (Otto and Wood, 2001) to generate and select the final concept variant, which was proven using a proof of concept prototype (Figure 1). The device must perform three basic functions: support a book, hold the pages open, and turn one page at a time. The concept we selected uses a rubber friction wheel roller assembly that rolls the top page into an arc loop near the binding. Then a cam hook disk-shaped mechanism (4) turns to a position where the hook protrusion enters the recess under the arc. The cam hook then continues to rotate, turning the page and stopping at its original position (Figure 2). The cam hook design obviates the need for a separate constraint assembly for the pages not being turned. We learned from the proof of concept that the roller needs to freewheel as the cam hook pulls the paper from underneath the wheel. For the alpha and beta prototypes we added a one-way clutch to the friction wheel roller for this purpose.

|

|

DESIGN EMBODIMENT

The final design phase was embodiment, which included detailed geometry and materials, testing and modeling analysis, creating a manufacturing plan, and building the alpha and beta prototypes. To electromechanically automate the alpha prototype (Figure 3), we designed an innovative control module, which uses a latching relay in conjunction with a series of timing switches driven off the cam hook motor shaft. The friction wheel roller assembly must be timed precisely so that the length of the arc of paper is 2.5 inches when the cam hook enters the recess.

Testing to optimize the friction wheel roller assembly continued on the alpha prototype to determine the nominal surface contact area and normal force on the page. This structured testing used tension, compression, and torsion springs, and restricted the change in gravitational force.

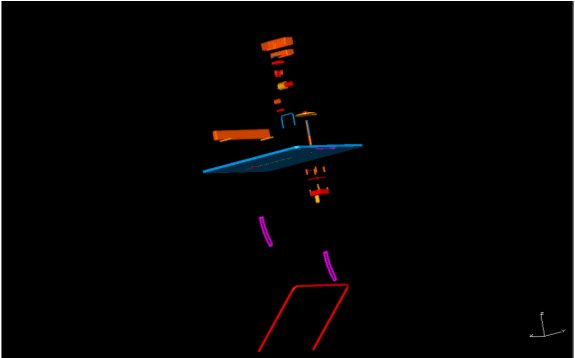

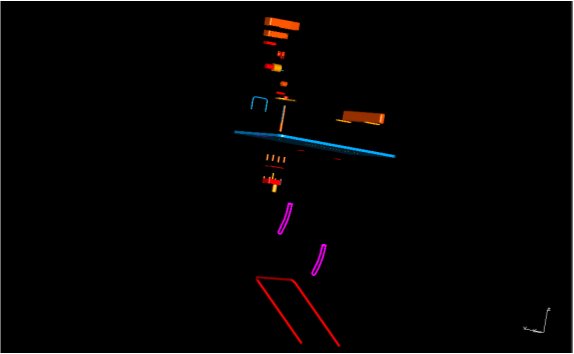

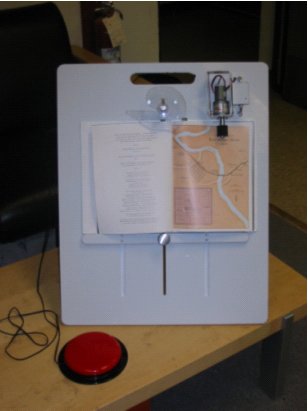

The customer was extremely pleased with the size, weight, and aesthetics of the alpha prototype. For the beta (Figure 4), we incorporated modeling and testing results, minor material changes, and we added an optional audio sensory feedback mechanism. We also enclosed both motors for safety and durability. All the components of the beta prototype are commercially available or machined, including the electronics, Lexan covers, and polypropylene base plate. At a Bill of Materials cost of $295.15, the beta prototype is under the threshold of $300, an extremely affordable option for school and private use, and is fully reproducible.

With product longevity in mind we also assembled a repair kit with a variety of extra hardware and a spare cam hook. This will greatly increase the page turner's product life cycle.

|

|

CONCLUSION

Our design team created an innovative, portable, durable page turning machine. Books and printed materials are a tremendous source of learning and enjoyment for people of all ages, and our device greatly increases the independence of people whose disabilities prevent them from interacting with these materials. Our design also costs thousands of dollars less than the average commercial page turner. The ability to turn pages and interact with printed media improves self-esteem and produces a higher quality of life, and facilitates the experiential learning process all students deserve.

REFERENCES

-

[Online], Available http://poisson.me.dal.ca/~dp_99_5/Images/Other/State_Of_The_Art.jpg for information on commercial page turners and their associated prices.

- [Online], Available http://www.delphion.com/fcgi-bin/patsearch and http://patents.cos.com/cgi-bin/search/main for information on existing page turning device patents.

-

K. N. Otto, K. L. Wood. (2001). Product Design. Prentice Hall, Inc., NJ.

-

Berger, John. G., Emmons; David. J. (To Regents of the University of Minnesota), "Page turning device," U. S. Patent 4,644,675, February 24, 1987.

ACKNOWLEDGEMENTS

We would like to thank all of the students, faculty, and staff of Rosedale School, especially Room 19 teacher Tom Hansen, for creating such a life-improving project. We express our sincere thanks to Dr. Kristin Wood and Dr. Richard Crawford for their unwavering support and guidance throughout the project. Thanks also to Eric Shafer for help with machining and fabrication.

Michelle M. Bailey

Department of Aerospace Engineering/Engineering Mechanics

WRW 415A, University of Texas at Austin, Austin

Texas, 78712

Page Turner Exploded View Left Side

Page Turner Exploded View Right Side

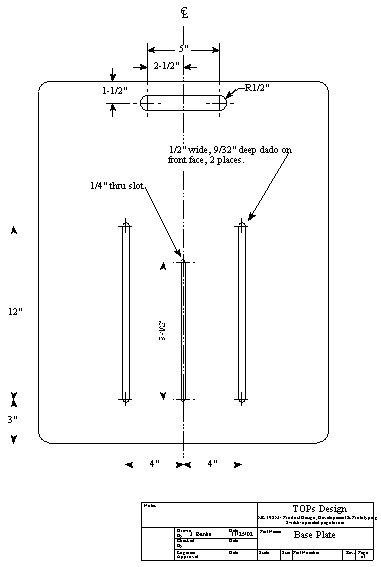

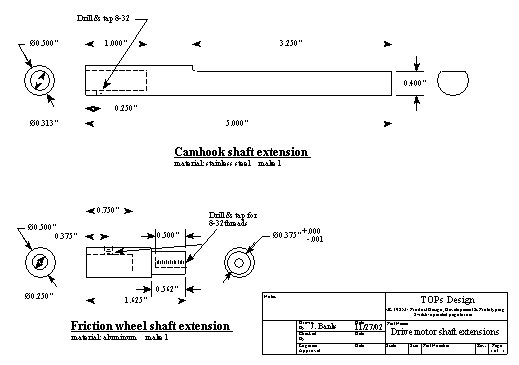

Shaft Extension Detailed Geometry

Friction Wheel Cover Detailed Geometry

VIDEO TAPE NARRATIVE

Background

We are a student design team from the Mechanical Engineering Department of the University of Texas at Austin. Our project is the design and construction of a switch-activated assistive page turning device to give people with disabilities more independence for interaction with printed materials. This project was originated by the Rosedale School of the Austin Independent School District, which has many students with multiple and severe disabilities.

Students with severe physical disabilities still have a desire to interact with a variety of printed materials such as books and magazines. Those who have limited or no finger, hand, or arm dexterity often find it difficult to turn pages. Because of this, they frequently require the assistance of another person while reading, and the process hampers their imagination, independence, and decision-making powers.

These requirements led to the desire for a switch-operated page turner. While there are several commercial devices on the market, most of them are too expensive for schools which may need several machines. In addition, the commercial units can be somewhat complex to set up and operate, and are not designed for ruggedness and durability. Our goal was a low-cost, simple to operate page turner for school use. It is designed to be compatible with standard push-button switches, to turn pages only in the forward direction, to be rugged, and to be compact for transportation and storage.

Basic functions and design

There are three basic functions that the device must perform. It must support books in position for good visibility, hold the pages open, and turn a single page at a time.

After extensive background research and concept generation, we came up with a set of components and built a basic proof-of-concept prototype, shown here. The idea was to form a loop or arch in the page to be turned, and then a pivoting arm would come in under the loop, and flip the page over.

Our system has a polypropylene baseplate with pivoting legs which allows the angle of the book to be varied. A sliding shelf supports the bottom of the book and holds it in the proper position; guides attached to the shelf allow easy one-hand adjustment. Spring clips restrain the cover and binding and keep the book from moving while in use. A friction wheel, similar to those in computer printers and copiers, feeds the page to be turned. The key component of the page turner is a camhook, which combines a transparent disk which holds the pages open with a pivoting arm which turns the page. The system is driven by a pair of DC gearmotors, and controlled by timing cams, roller switches, and a relay. A 1/8" phone jack allows the use of standard `jellybean' switches, commonly used by children with disabilities for a wide range of applications.

This is our alpha prototype, the first working electromechanical version. The final beta prototype, delivered to the customer, is essentially similar, but with improved operation, more finished and ruggedized components, and a sound feedback and reinforcement system.

Detailed components and operation

The friction wheel drive is mounted on a pivot, which allows it to remain in contact with the top page while progressing through the book. (Books up to 1-1/2" in thickness can be used with our device.) A spring maintains the proper force between the wheel and the page so that only a single page is turned at a time. The wheel feeds the page only enough to form the loop, without going past the edge of the page. A one-way roller clutch allow the feed wheel to roll without resistance as the remainder of the page is pulled out while turning.

The camhook serves two functions. Most of the disk acts to hold the pages open. As it rotates during page turning, however, a notch allows the page loop to open fully, and then the "hook" arm passes under the loop, turns the page to the opposite side, and then constrains the pages in the new position.

The system is activated by a signal from the user-operated switch, which turns on a latching relay supplying power to the motors. A pair of timing cams and roller switches mounted on the camhook motor shaft control the timing and sequence of the feed roller motor stops the camhook at the end of the cycle, and activates the sound feedback.

Because a standard switch interface is used for control input, it would be easy to adapt the system for timers or other automated activation systems.

Conclusion and summary

We believe that our device will improve the educational experience for the students at Rosedale School and give them much greater independence for interacting with printed materials. While this machine was developed for a specific group of users, it can be used in other school settings, and can be adapted for the general community of people with disabilites, providing improved quality of life.