Assistive Technology and the Product Design Cycle: Designing a Letter Folder

ABSTRACT

In a graduate level engineering course entitled Modern Product Design at the University of Missouri-Rolla, Drs. Stone and McAdams present a variety of design techniques based on current research to provide a systematic approach toward product design. These design techniques are employed to design a letter folder that will benefit handicapped workers at the Rolla Area Sheltered Workshop who do not have the necessary skills to tri-fold letters for bulk mailings.

KEYWORDS

Letter folder, letter folding, sheltered workshop, assistive technology

BACKGROUND

One of many jobs performed at the Rolla Area Sheltered Workshop (RASW) involves the preparation of bulk mailings. The task is currently completed by an assembly line of three workers: the first person manually tri-folds the letter and hands the letter to the second person; the second person stuffs the letter into an envelope and then seals the envelope; the third person properly aligns and applies a self adhesive mailing label to the envelope. The primary problem in this process is that many of the individuals employed at the Workshop lack the skills required to tri-fold paper. Supervisors at the RASW generally try to rotate the workers to a different job every hour, but because manual letter folding requires more skill than many workers possess, the same small number of workers are required to continually perform the task of letter folding.

Sheltered workshops represent the primary market for the product presented here. Although the product is being designed to assist individuals who are disabled, the product is also expected to be usable by those who do not have a disability. There are currently 90 Workshops in Missouri (1).

OBJECTIVE

The goal of this project is to design a device that will reduce the amount of skill required to accurately and safely fold letters without displacing the job of the worker who would otherwise perform the task of letter folding.

METHODOLOGY

Stone and McAcams used the Keirsey Temperament Sorter to divide the class of 18 students into four design teams based on individual personality traits (2). With a variety of personalities represented in each team, the team members were expected to learn from members who excel in other areas. As a result of the observance of personality differences, the level of problem solving ability across the team likely increased (3).

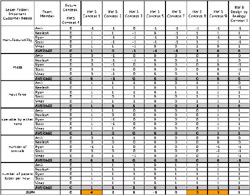

After our team identified the letter folder as our project, our foremost task was to accurately identify customer needs (CN). To do this, we visited the RASW to watch firsthand the preparation of bulk mailings. During this time, we also interviewed the supervisors to determine their expectations for the letter folder we would be designing. We combined our observations with the results from the interview into a large list of potential CN. We then returned to the RASW and asked each of the four supervisors to complete a questionnaire containing our list of potential CN. The supervisors rated each CN from zero to five with zero indicating the CN is ‘not needed' and five indicting the CN ‘must' be represented in the design. We averaged the completed questionnaires to arrive at the list of CN shown in Table 1.

| Customer Needs | Scaled Customer Need Rating |

|---|---|

| Accept a stack of paper | 5 |

| Accept paper size of 8 1/2" x 11" | 5 |

| Have a portable base | 5 |

| Not completely automated | 5 |

| Operate the machine with either hand | 5 |

| Safe operation | 5 |

| Accept variable paper thickness | 4 |

| Be portable | 4 |

| Completely mechanically-operated machine | 4 |

| Easy operation (small effort to operate) | 4 |

| Easy to clean | 4 |

| Fold paper precisely from corner to corner | 4 |

| Low maintenance | 4 |

| Provide an electrical connection to power a motor | 4 |

| Amount of noise tolerated with 1 representing a loud noise | 3 |

| Capable of being fastened to a table | 3 |

| Only one fold of paper is folded at a time | 3 |

| Aeshtetically appealing | 2 |

|

|---|

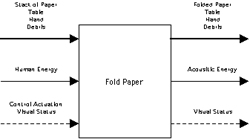

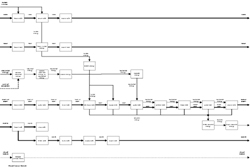

The next step in the design process involved creating a black box model and a functional model, which provided an essential link between CN and product functionality. In order to accomplish this, the CN were mapped to letter folder input and output flows. These flows were then used to create the black box model shown in Figure 1. After creating the black box model, we used the “Zen” approach and the Functional Basis to create the functional model shown in Figure 2 (4-5). To perform the “Zen” approach, we imagined ourselves as the flows represented in the black box model, and we essentially “became the flow” to determine what functions act on the flow as the flow progresses through the system. The purpose of a functional model is to represent a form independent blueprint of the product (4). The Functional Basis is a standardized list containing concise definitions of verbs and objects that are combined to form the function-flow pairs in a functional model. Functional models allow product architecture decisions to be made early in the design process as these models are abstract and provide a means for creative solutions (4).

|

|---|

Various methods were employed during the conceptual design stage to produce approximately 30 different letter folder sketches. These methods included: morphological analysis, modular heuristics, Design by Analogy, C-sketch and the concept generator approach (6-9). The resulting concept variants were screened using the Pugh chart in Table 2. The high-ranking concepts from the Pugh chart were scored using decision matrices to ultimately arrive at the selected concept shown in Figure 3. Although the depicted concept uses belts to drive the rollers, the concept was chosen with the understanding that gears would be used in place of the belts for the sake of simplicity.

|

|---|

RESULTS

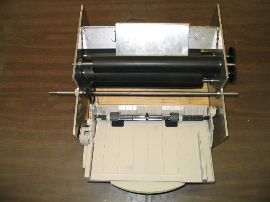

Once the concept was selected, engineering specifications were derived and a physical proof of concept test was performed. We obtained four rollers with meshing gears from two typewriters and two printers that were donated from university surplus. A tray with a paper separating mechanism was also obtained from one of the printers. We machined each of the rubber rollers (which were bonded to a metal shaft) to the same diameter and crudely mounted the rollers, gears, a DC motor, and slotted blades (part of the mechanism that causes the paper to fold) to supporting aluminum to demonstrate the feasibility of the letter-folding concept. An Alpha prototype was then built and demonstrated to the supervisors at the RASW to obtain their feedback regarding the current state of the design. The final prototype, the Beta, is shown in Photo 1 with the cover and shaft/gear guards removed.

|

|---|

Our manufacture of the prototypes required advanced technical skills to operate a CNC mill and a CNC lathe, which were used to reduce our production time. A production letter folder would require less advanced and less expensive equipment and could be easily built by a small machine shop.

DISCUSSION

To operate the letter folder, the user places a stack of 50 papers in the input tray and toggles the power switch. The switch actuates the motor that continuously turns the gears and rollers. The user then manually operates a lever attached to the paper separating mechanism to cause a single paper from the stack to be fed into the rollers. The paper is tri-folded and ejected.

REFERENCES

- http://www.moworkshops.org/Officers_Districts.html . September 15, 2003

- http://keirsey.com/ . August 25, 2003.

- McCaulley, M. H. (1990). The MBTI and individual pathways in engineering design. Engineering Education, July/August, 537-540.

- Stone R. B. & Wood K. L. (2000). Development of a Functional Basis for Design. Journal of Mechanical Design, 122(12): 359-369.

- Hirtz J., Stone R. B., McAdams D. A., Szykman S., & Wood K. L. (2002). A functional basis for engineering design: Reconciling and evolving previous efforts. Research in Engineering Design, 13, 65-82.

- Otto K. & Wood K. (2001). Product design: Techniques in reverse engineering and new product development, 425-426, 454-456.

- Stone R. B. & Wood K. L. (2000). A heuristic method for identifying modules for product architecture. Design Studies, 21, 5-31.

- McAdams D. A. & Wood K. L. (2000). Quantitative measures for design by analogy. Proceedings of Design Engineering Technical Conferences. DETC2000/DTM-14562.

- Strawbridge Z., McAdams D. A., & Stone R. B. (2002). A computational approach to conceptual design. Proceedings of Design Engineering Technical Conferences. DETC2002/DTM-34001.

Author Contact Information:

Scott Uder,

University of Missouri-Rolla,

Design Engineering Lab,

G5 Basic

Engineering Building,

Rolla, MO 65409,

Office Phone (573) 341-6064

EMAIL: sjuder@umr.edu