Manual Wheelchair Propulsion Patterns on Natural Surfaces

Bailey Roche1,2 ; Alicia Koontz1,2,3; Megan Yarnall1,2 ; Jennifer Mercer1,2 ; Rachel Cowan1,3 ; Michael Boninger1,2,3

Human Engineering Research Laboratories, Highland Drive VA Medical Center, Pittsburgh PA1

Department of Bioengineering, University of Pittsburgh2

Department of Rehabilitation Science and Technology, University of Pittsburgh3

ABSTRACT

Studies investigating wheelchair propulsion patterns are inconsistent regarding the observed usage of each pattern and benefits of using a particular technique. The aims of this study were to classify propulsion patterns over natural surfaces and to compare selected biomechanical variables between pattern types. Twenty-nine wheelchair users propelled over carpet, linoleum, and up an 8.3º ramp while kinematic and kinetic data were collected. On linoleum, persons using the semi-circular and double-looping techniques contacted further back on the pushrim (p=0.044) and tended to have lower average forces (p=0.083) and lower stroke frequency (p=0.072). Persons not using an arc pattern pushed faster (p=0.04) on the ramp without using more force. Using a non-arcing pattern may reduce the risk of upper limb pain and injury.

KEYWORDS:

Wheelchair, Propulsion, Biomechanics, Pattern, Technique

BACKGROUND

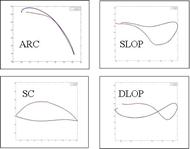

Figure 1: Examples of each propulsion pattern (ARC – arcing, SLOP – single looping over pushrim, SC – semi-circular, DLOP – double looping over pushrim.) (Click for larger view)

Figure 1: Examples of each propulsion pattern (ARC – arcing, SLOP – single looping over pushrim, SC – semi-circular, DLOP – double looping over pushrim.) (Click for larger view) Manual wheelchair propulsion, among other strenuous upper limb tasks, predisposes individuals with spinal cord injury (SCI) to upper-extremity pain and injury (1). During propulsion, the hand is constrained to following the arc of the pushrim when applying force but is free to move in various directions upon hand release in preparation for the next stroke (e.g. during the recovery phase). Previous studies have identified four different patterns that the hand follows after releasing the handrim (2). Figure 1 shows examples of the four patterns: semi-circular (SC), single looping (SLOP), double looping (DLOP), and arcing (ARC).

Biomechanical investigations have been conducted to determine if a particular pattern has any benefit to wheelchair users. Boninger et al. evaluated 38 wheelchair users with paraplegia on a wheelchair dynamometer and concluded that the SC pattern has the lowest push frequency and a higher ratio of time spent applying forces to rim compared to time spent off the rim (2). Another study found that propelling with lower stroke frequencies may keep wheelchair users from developing median nerve injuries (3). Spending more time on the pushrim allows for forces to be distributed over a longer distance which could potentially minimize high impact forces to the upper limbs (3). A recent study by Richter et al. however, did not find anyone in their sample of 26 manual wheelchair users who used the SC pattern (4). This study classified patterns on a treadmill at level and two different grades. They found that most users, if not already using an ARC pattern, will switch to an ARC pattern while pushing uphill (4). All the studies to date have classified propulsion patterns on artificial surfaces such as a dynamometer or a treadmill, which could alter the user’s natural technique. Therefore, prior study findings may not apply to everyday wheelchair use.

The aims of this study were to classify propulsion patterns of manual wheelchair users over natural surfaces and to compare propulsion variables (e.g., pushrim force and moment, velocity, start/release and contact angles, and frequency) between the pattern types for each surface (linoleum, carpet, and ramp).

METHODOLOGY

Experimental Protocol:

The study took place at the National Veterans Wheelchair Games in Minneapolis, MN in 2005. Persons who owned a manual wheelchair and had no history of upper limb fractures or dislocations that they have not recovered from were included in the study. A six camera Vicon MX motion camera system (Vicon, Centennial, CO) was used to record at 60 Hz the position of the third metacarpalphalangeal joint (3MP), as well as the rear axle of the subject’s manual wheelchair during propulsion. The six Vicon cameras were aligned next to each other and facing the left side of the wheelchair user. On the left side of their personal wheelchair a SMARTWheel (Three Rivers Holdings, Inc., Mesa, AZ) was attached. This instrumented wheel collected three-dimensional pushrim force and moment data and average velocity of the wheel at 240 Hz for each propulsion cycle.

The surfaces tested included level linoleum, high-pile carpet, and a plywood ramp with an 8.3o grade. As all the testing was done in one room, linoleum and carpet remnants were purchased and a ramp was constructed. Each was positioned in front of the cameras which remained stationary throughout the testing. The linoleum remnant was 4’ by 15’, the carpet remnant was 5’ by 15’ and the ramp was 4’ by 12’ with a 4’ x 4’ platform landing at the top. A metal strip (4’ by 1’) was placed at the bottom of the ramp to ease the transition from a level surface to an incline. Each surface was completed in a random order. Subjects started from rest and pushed to a steady-state comfortable pace. Kinetic and kinematic data were synchronized and collected over the entire surface however; only one steady state stroke for each subject was analyzed. The steady state stroke was defined as the fourth stroke after starting from rest (5), but in the case where the subject did not have four strokes for a given trial the last stroke was analyzed. This situation only occurred on the linoleum because rolling resistance was lower and it was easier for some subjects to attain and maintain a comfortable pace with fewer strokes. Three trials over each surface were recorded and a total of nine strokes per subject (3 strokes per surface) were included in the analysis.

Data Analysis:

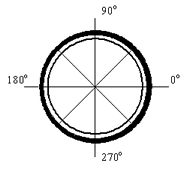

Figure 2: Wheelchair wheel with coordinate reference system for describing angles of impact and release on the pushrim. (Click for larger view)

Figure 2: Wheelchair wheel with coordinate reference system for describing angles of impact and release on the pushrim. (Click for larger view) The hub position was subtracted from the position of the 3MP in order to create pattern plots for analysis. The SMARTWheel data was down-sampled from 240 Hz to 60 Hz and was used to identify when the hand was on the pushrim and to separate the strokes. A computer program was created (Matlab, Mathworks, Inc.) to display all 261 pattern plots (3 trials (3 strokes) x 29 subjects x 3 surfaces) at random to five researchers who independently classified the pattern into one of the four types previously defined. The researchers were comprised of two manual wheelchair users with SCI and three others who were familiar with the prior literature on propulsion patterns. A single stroke (for each surface) having the highest consensus for a single pattern type was selected for further analysis. The biomechanical variables: peak and average resultant force and moment about the hub, average velocity, and stroke frequency were determined for each stroke. In addition, the 3MP and axle position was used to determine the impact, release and contact angles on the pushrim (see figure 2).

Subjects were grouped according to the pattern type they used for each surface. The SC and DLOP patterns each had small numbers of subjects and since these patterns share similar characteristics (e.g., the hand is below the pushrim for a substantial period of the recovery phase), subjects using these patterns were combined into one group (for linoleum and carpet). Twenty-three people used ARC on the ramp while six people used one of the other three pattern types and therefore the six people formed one group. Analysis of variance (ANOVA) tests were performed on the linoleum and carpet data to compare the propulsion variables between pattern types. An ANCOVA test was used on the ramp data to control for the difference found for average velocity (determined initially with an independent t-test). Since weight can influence the force used to propel, we measured body and wheelchair weight using a wheelchair scale and compared combined weight across the subject groups. If a difference was found, we intended to use an ANCOVA test controlling for weight. The level of significance was set to 0.05.

RESULTS

Twenty-eight men and one woman were recruited into the study and provided their informed consent. The average age of the subjects was 46.7±9.7 years. The average years since injury was 14.2±9.9 years. There were 24 total subjects with spinal cord injury, 17 of which had thoracic injuries, five had lumbar injuries, and five had cervical injuries. Two subjects had a bilateral transtibial amputation, one subject had a unilateral transfemoral amputation, one subject had peripheral neuropathy, and another subject had spina bifida at L4.

As rolling resistance of the surface increased, the number of subjects using the ARC pattern increased (Tables 1-3). On linoleum, persons using DLOP/SC placed their hand further back on the rim upon impact (p=0.044). Also, the DLOP/SC group tended to have smaller average forces (p = 0.083) and lower stroke frequency (p=0.072). On carpet the DLOP/SC group also tended to place their hand further back on the rim at impact (p= 0.084). On the ramp, the ARC group pushed more slowly (p=0.04) and tended to contact further up on the rim (p-0.054) than the group using one of the other three patterns. After controlling for the difference in velocity (ramp only), there were no differences in any of the propulsion variables. Body and wheelchair weight combined was not significantly different between the subject groups for any surface.

| TILE | ARC N=13 (44%) | SLOP N=7 (24%) | DLOP/SC N=10 (33%) | Sig. | |||

|---|---|---|---|---|---|---|---|

Peak Resultant Force |

91.42 |

-21.17 |

101.07 |

-31.31 |

82.39 |

-25.99 |

0.356 |

Average Resultant Force |

42.11 |

-14.1 |

50.68 |

-15.41 |

35.98 |

-5.43 |

0.083* |

Peak Moment |

18.95 |

-5.24 |

21.67 |

-5.91 |

16.39 |

-6.84 |

0.228 |

Average Moment |

5.73 |

-2.28 |

6.99 |

-2.24 |

5.6 |

-2.09 |

0.403 |

Average Velocity |

0.99 |

-0.15 |

0.92 |

-0.18 |

0.99 |

-0.26 |

0.738 |

Impact Angle |

110.97 |

-10.39 |

117.28 |

-6.04 |

121.52 |

-9.6 |

0.044** |

Release Angle |

58.65 |

-10.11 |

55.08 |

-8.12 |

64.06 |

-10.74 |

0.202 |

Contact Angle |

52.32 |

-18.97 |

62.2 |

-9.95 |

57.46 |

-15.78 |

0.431 |

Stroke Frequency |

2.15 |

-0.32 |

1.84 |

-0.34 |

1.79 |

-0.48 |

0.072* |

Body + Wheelchair Weight |

116.8 |

-28.13 |

118.52 |

-22.03 |

95.38 |

-13.06 |

0.076* |

| * = p < 0.1 ** = p < 0.05 |

|||||||

DISCUSSION

Our study found ARC to be the most common pattern on level linoleum consistent with the prior treadmill study that simulated propulsion on a smooth, level surface (4). However, we found in this study that the group who used the DLOP/SC pattern contacted the rim further back and pushed with less force and lower stroke frequency. In a prior study by de Groot et al., 25 novice able-bodied subjects were taught to use the ARC, SLOP and SC patterns (6). They propelled using each pattern type on a wheelchair ergometer at different speeds (1.11 m/s and 1.39 m/s) at the same resistance (0.23 N/kg). The ARC pattern was shown to require slightly less metabolic energy (7.1% and 7.6% for both velocities) than the SC pattern (6.7% and 7.0%) however ARC had significantly higher cycle frequency (varying between 1.02 and 1.17 cycles per second) than SC (varying between 0.88 and 0.93 cycles per second). These results provide further indication that the SC pattern of propulsion may be better from an injury prevention perspective. Should a metabolic analysis of stroke patterns in actual wheelchair users confirm the findings of the de Groot study (6), more likely than not, the small amount of energy that is saved by using an arcing pattern will not outweigh the adverse life changes that can result from the onset of upper limb pain and injury.

Reasons why we may have found more people using an ARC pattern compared to the other patterns may be because most wheelchair users do not receive any training on propulsion techniques or have an improper wheelchair setup. The individuals using DLOP/SC in this study may have their chairs setup to be more conducive to using this type of pattern. For instance if the rear wheel is further forward with respect to the seat, it’s easier to reach back on the pushrim. A more forward wheel in turn can help reduce the chair’s rolling resistance, thereby minimizing the forces needed to propel and reducing stroke frequency. This may be another reason why the subjects using patterns other than ARC in this study were able to push faster up the ramp without using significantly higher forces.

CONCLUSIONS

This study found that a large percentage of manual wheelchair users use an arcing pattern of propulsion despite the potential benefits of using a DLOP/SC pattern in reducing forces and stroke frequency. The small numbers of subjects using DLOP/SC limited our ability to find greater differences but trends in the data were apparent. As wheelchair users spend a majority of their time propelling on smooth and level surfaces, using a DLOP/SC pattern may minimize their likelihood of developing upper limb pain and injury. The reasons that arcing may be more prevalent may be due to a lack of training in proper propulsion techniques or a poorly fitted wheelchair. Future work should confirm these study findings with a larger group of wheelchair users who do not all participate in organized wheelchair sporting events.

REFERENCES

- Gellman H, Sie I, Waters RL. Late Complications of the Weight-Bearing Upper Extremity in the Paraplegic Patient. Clin Orthop 1988;233:132-5.

- Boninger,M.L.; Souza,A.L.; Cooper,R.A.; Fitzgerald,S.G.; Koontz,A.M.; Fay,B.T. Propulsion Patterns and Pushrim Biomechanics in Manual Wheelchair Propulsion. Arch.Phys.Med.Rehabil. 2002 May; 83(5):718-23

- Boninger ML, Koontz AM, Sisto SA, Dyson-Hudson TA, Chang M, Price R. et al. Pushrim biomechanics and injury prevention in spinal cord injury: recommendations based on CULP-SCI investigations. J Rehabil Res Dev 2005; 42(3):9-20.

- Richter M, Rodriguez R, Woods K, Axelson P. Is There a Best Way to Follow-Through Between Pushes? Proceedings of the 29th Annual RESNA Conference, Atlanta, GA, CD-ROM, June 22-26, 2006.

- Koontz AM, Cooper RA, Boninger ML, Yang Y, Impink BG, van der Woude L. A kinetic analysis of manual wheelchair propulsion during start-up on select indoor and outdoor surfaces. Journal of Rehabilitation Research & Development. 42(4), 2005, 447-458.

- de Groot S, Veeger HEJ, Hollander AP, van der Woude LHV. Effect of Wheelchair Stroke Pattern on Mechanical Efficiency. Journal of Rehabilitation Research & Development 41[2], 69-70. 2004.

ACKNOWLEDGEMENTS

The VA Center on Wheelchairs and Related Rehabilitation Engineering B3142C

The NIDRR Collaboration on Upper Limb Pain in Spinal Cord Injury H133A011107

The Paralyzed Veterans of America

Bailey Roche

Human Engineering Research Laboratories,

7180 Highland Dr., 151R1-H

Pittsburgh, PA 15206

Email: baileyroche@gmail.com

Highlights

- Source Ordered

- No Tables

- Very Compatible

Gargoyles

Disney produced a television show in the mid 1990s called Gargoyles. It's a great show and I'm a big fan. A few years ago Disney started to release the show on DVD. The last release was of season 2, volume 1. That was two years ago. Volume 2 has not been released. Why? Poor sales. So if you should find yourself wanting to support my work, instead I ask you pick up a copy of season 2, volume 1. It's a great show and you might find yourself enjoying it.