Foot-Action Guitar Strummer

Jonathan Lee, Jason Leung, and Matthew Topel

Duke University

Durham, NC 27708

ABSTRACT

A strumming device has been created to enable individuals with disabilities to play the guitar using one hand and a foot pedal. The strumming mechanism is composed of a “pick rod”, which holds six individual guitar picks, and two complementary-action solenoids that move the rod across the strings. The strumming mechanism is mounted to the guitar face and is controlled by a momentary switch within a foot pedal. The entire system is powered by an AC/DC converter that plugs into a wall socket. The device is portable, produces good sound quality, requires minimal user effort, and is useful for individuals with decreased dexterity on one side of their body.

KEYWORDS:

guitar strummer; musical device; pick rod; automated strum; hemiplegia

BACKGROUND

The client is a 17 year-old man who had a left hemispheric stroke at the age of three that affected the right side of his body. Because of the stroke, he does not have the dexterity and fine motor control necessary in his right arm to strum a guitar. Five years ago, he decided that he wanted to learn how to play the guitar. Because no commercially available devices existed, a student design team at Duke developed a device that simulated a guitar strum by striking a rod across the guitar strings in a hammering motion. The rod was actuated by a foot pedal that the client could use with his left foot (Bennett and Laverde 2002).

The device had several faults that resulted in complete nonuse by the client. The sound quality of the device was mediocre, and the device required significant effort, which led to leg fatigue. Portability was also limited due to the large pedal and permanently connected components.

The client now desires a new device that is similar in concept, but improves upon the previous device in three critical areas: sound quality, ease of use and portability.

PROBLEM STATEMENT

The main goal of this project is to create a device that will strum a six-string guitar using a foot pedal. Primary objectives are to develop a device that produces a sound quality similar to the hand strumming of a guitar, requires very little effort to use, and is portable.

DESIGN AND DEVELOPMENT

The design process sought to address the main needs of our client while improving upon the faults of the previous design. Our primary decision was to determine whether to implement a leg-powered mechanical strummer that would allow for enhanced strumming sensitivity, or an electrically powered strummer that would require less force from the user.

Our preliminary mechanical design relied on a cord that retracted when a foot pedal was pressed. The cord was connected to a platform that had a pick and sat on a track situated above the face of the guitar. During testing of a prototype of this design (photo 1), we found that the track resistance caused unnecessary fatigue for the user. Our electrical design prototype incorporated a switch-powered solenoid to actuate the guitar strum, and the force required by the user to strum the guitar became negligible. Because of its ease of use, we pursued the electrical design.

Our prototype for the electrically-powered strummer (photo 2) consisted of a single, spring-loaded push-type solenoid attached to a pick rod. The pick rod housed six guitar picks, and when the solenoid was activated, the pick rod moved across the strings and created a strum. The pick rod was constructed from Delrin, an abrasion resistant plastic, such that the displacement needed for the whole pick rod was reduced to 3/8”, smaller than the ½” displacement of the solenoid. A hole was milled along the axis of the pick rod to accept the solenoid plunger, and a set screw was used to secure the pick rod to the plunger.

We built a temporary mounting stage to test the idea, and the sound produced was promising; however, it was difficult to find a spring stiff enough to recoil, while being weak enough to allow strong strum in the push direction of the solenoid. Furthermore, a standard 9V Duracell battery was fully drained after 2.5 minutes of playing.

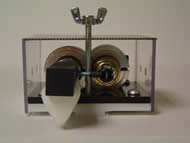

In our final design (photo 3), we address the problems with the prototype. One push and one pull solenoid are connected together and to the pick rod, which allows robust strumming, and independent timing, for both the up-strum and down-strum. Both solenoids draw power from a 12V, 5A AC/DC converter, which allows the strummer to be activated indefinitely. A 1/8” stereo plug connects the AC/DC converter output to a corresponding jack from the foot pedal (photo 4a, 4b). A single pole double throw (SPDT) switch diverts power to the solenoid component (photo 5) so that one solenoid is activated at all times: pressing the pedal activates one solenoid while releasing the pedal activates the other. This method of control allows for a playing speed comparable to hand strumming. A ¼” stereo guitar cable connects the signals from the SPDT switch in the pedal to the solenoids on the guitar; this standard cable, available at many music stores, is easily removed by unplugging both ends. Because each connection in the system uses a different sized plug and jack, it is impossible to connect the components incorrectly. The surfaces of the push solenoid are padded with neoprene to mitigate excess noise from the solenoids stopping and starting during operation; these sounds were originally distracting but are now subtle. To dissipate heat from the solenoids, conductive zinc collar clamps secure the solenoids to a base plate, and a plexiglass enclosure with air holes prevents contact with the solenoids, which become hot during use.

The strumming components are attached to the guitar via a sliding track mounted on the guitar, which guides the strummer into position. Ball detents on the track allow for easy and consistent positioning, and a wing nut screw fixes the strumming components to the sliding track.

Finally, we have provided the ability to adjust the height of the mounted system by connecting the base plate to another mounting platform (photo 7). Because the precision of the device is very important to the quality of function, allowing for small height adjustments adds to the robustness of the device (photo 8).

EVALUATION

The device was tested to determine the maximum strumming rate and the temperature escalation over time. The maximum strumming rate was 17 strums per second corresponding to 9 pedal presses and 8 releases per second. This high frequency should prevent strumming rate from being a limiting factor in any musical composition. The temperature of the solenoids rose sharply to a high temperature of 140°F. However, the enclosure, and specifically the top cover of the enclosure, maintained a safe temperature of 89.6°F degrees, protecting the user from potential injury.

DISCUSSION AND CONCLUSIONS

The foot-action guitar strummer allows our client to play the guitar using one arm and one foot. The major advantages of this device include realistic sound quality, ease of use, and portability. One prominent disadvantage is that the device does not allow for the strumming of individual strings, and while undesired strings can be muted, the effect is not comparable to strumming one string alone. The device also heats up rapidly due to the constant activation of the solenoids. This problem has been addressed by using heat-sinking mounts for the solenoids and a protective plastic enclosure to prevent the user’s hands from touching the solenoids. A hammering noise is present during use due to the movement of the solenoid plungers. This problem has been minimized by adding shock-absorbing materials on the plungers to mute the contact sound. Finally, the strumming volume cannot be varied dynamically, since it is determined by the fixed height of the picks relative to the strings. The device was custom-designed for the client’s student-sized acoustic guitar and would require modifications for guitars with different geometries, particularly different string spacing. Adaptation to electric guitars would require a new mounting system. Future work could include developing a device to allow strumming of individual strings, a reduction in the size of the strumming device, and potentially a battery-powered design that would remove the need for cords between the pedal and guitar. The foot-action guitar strummer has met its objectives, and will allow our client to learn to play the guitar.

REFERENCES

Bennett, Jason and George LaVerde. “Guitar Strummer.” NSF 2000 Engineering Design

Projects to Aid Persons with Disabilities. Eds. John D. Enderle and Brooke Hallowell. Creative Learning Press (2002) 64-5.

ACKNOWLEDGMENTS

This material is based upon work supported by the National Science Foundation under Grant No. 0118558. We would like to thank our professor, Dr. Laurence Bohs, who provided invaluable guidance. We would also like to thank Joe Owen and Gabriel Howles for their help in machining difficult parts.

Author Contact Information:

Jonathan Lee

P.O. Box 97786

Durham, NC 27708

Jason Leung

P.O. Box 97512

Durham, NC 27708

Matthew Topel

P.O. Box 97142

Durham, NC 27708