Biomedical Engineering, Duke University

ABSTRACT

The goal of this project was to enable employees with disabilities at OE Enterprises, Inc. to quickly and safely apply contact cement to pieces of foam insulation. Contact cement is used to glue foam pieces together to make insulation for pipe joints. We designed and built a device that allows employees to swipe pieces of foam across a rotating roller to apply a thin, even layer of contact cement. The device was designed to be easy to use, easy to clean and made from readily available components. The employees at OE preferred using the device to the old method of manually brushing on contact cement. The device makes the task of applying contact cement to foam pieces more accessible to employees with a wider range of disabilities. Our device will benefit the employees by allowing them to work faster and more reliably in order to create quality insulation elbow joints.

KEYWORDS:

Roller, foam, glue tray, contact cement

BACKGROUND

Our clients are employed by OE Enterprises, a non-profit rehabilitation organization dedicated to maximizing the vocational potential of people with a wide range of disabilities. OE provides training and supervision to employees who perform various tasks contracted by external companies. Armacell, an insulation manufacturer, has contracted with OE to assemble pipe insulating foam elbow joints. The process occurs in two steps: gluing and assembly. According to OE, gluing is the bottleneck. The elbow joints are created from two or three angled pieces of foam tubes glued together by contact cement. The foam tube pieces have varying inner and outer diameters due to Armacell’s needs and manufacturing tolerance. The traditional method is to manually apply glue onto each surface using a brush, requiring each employee to have proficient manual dexterity. Brushing is slow, tedious, inefficient, and can cause contact cement to get on the exterior of the foam piece. Joints with contact cement on the exterior are rejected by Armacell and cannot be used.

PROBLEM STATEMENT

The goal of this project is to create a foam gluing mechanism for people with disabilities.

DESIGN

OE requires a safe, chemically-non-reactive device that performs better than using a brush by hand and makes the task more accessible to its employees. It should prevent spills onto the outside of the foam pieces, provide 100% coverage to different sized surfaces, and be easily manufactured using commercially available components. The last requirement was important in our design since OE plans to make duplicates of our device for their various locations and as their contract with Armacell grows larger.

Some feasible solutions we considered were a stamp pad, motorized glue roller with tray, and glue drip system with applicator. To establish the best solution, we first needed to find the best non-reactive material that provided 100% contact cement coverage to foam surfaces. We tested a variety of paint and adhesive rollers as well as foams, fabrics, and sponges. Some materials quickly reacted with the contact cement while others applied either too much or too little glue onto the foam pieces. A commercially available smooth paint roller best met the functional specifications.

From these results, a glue roller within a tray was determined to be the best solution, which we developed into the final device (Figure 1). This method utilizes the paint roller and best accommodates the different inner and outer diameters of foam pieces. A rotating glue roller inside a reservoir of contact cement allows the client to quickly and efficiently apply glue using a single wiping motion across the roller.

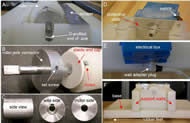

Two glue trays were constructed, one for a 9 inch roller and the other for a 4.5 inch roller in order to accommodate the different sizes of foam and prevent excessive drying of the contact cement. The glue trays were made out of high density polyethylene (HDPE) to withstand the solvents in both the contact cement and lacquer thinner, used for cleaning. The fabrication process consisted of cutting and milling blocks of HDPE to fit the two roller sizes. A hole and slot were then milled on either end of the glue tray for insertion of the axle, allowing the roller to rest just above the bottom of the glue tray (Figure 2A).

We determined that as the roller turns about the axle and picks up more glue, excess glue needs to be scraped off the surface of the roller before the client can use the device effectively. An adjustable scraper, made of sheet aluminum, was constructed with slits and attached to one side of the glue tray with screws and washers (Figure 2A).

The axle in the center of the roller was made from a steel rod with two D-profiled sections, one for the roller-axle connector and the other for the D-profiled connector. The roller-axle connector was attached to the axle with a set screw. The plastic end cap was then screwed onto this connector to keep the roller spinning with the axle. A screw on the plastic end cap kept the roller from slipping (Figure 2B). The end of the axle was milled to mate the roller with the motor side of the D-profiled connector without slippage (Figure 2C).

The connector, made of aluminum, was drilled to accommodate the different radii of the axle and motor driveshaft (Figure 2C). Side by side holes were tapped along the long axis of the connector for set screws. The connector allows the motor driveshaft and axle to turn in unison. The set screw used to hold the axle in place was loosened in order for the axle to easily slide in and out of the connector. A clear, protective plate was placed over the D-profiled connector to prevent injury due to moving parts. It also maintained visibility for aligning the D-profiled connector and the axle (Figure 2D).

The motor and all electronics were enclosed in a plastic electrical box for the safety and convenience of our clients and their supervisors. An LED switch attached to the box was used to turn the device on and off and lit up when the device was on. A 12V wall adapter was used to power the motor (Figure 2E). The glue trays were designed to fit within support walls securely attached to a wide base, complete with rubber feet. This ensured stability and prevented any potential movement of the glue tray as the client exerted forces on the device during use (Figure 2F).

Our device was designed for easy cleaning. The glue tray can be detached from the rest of the frame and completely submerged in lacquer thinner. After 30-60 minutes, the supervisor can clean the glue tray with stripping gloves and a metal-bristled brush. The roller can easily be removed and discarded after each day’s use.

DEVELOPMENT

The development of the Universally Accessible Contact Cement Applicator started as a paper model that was made into reality using spare parts from the lab. After testing with clients, a second prototype was made that did away with the pulleys. Additional client testing on the second prototype showed that the in-feed table hindered gluing, the adhesive applicator roller got too much glue on the exterior of the foam pieces, and the PVC did not withstand cleaning in lacquer thinner. This feedback was incorporated into the final device.

EVALUATION

The Universally Accessible Contact Cement Applicator has been in use at OE Enterprises for one month. Jamie Gillis, OE’s Business Development Manager, reported that the device not only increased efficiency, but allowed clients, whom otherwise would not have been able to, to perform the task.

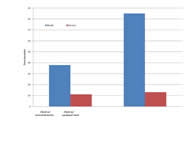

The device was delivered to OE Enterprises on March 23, 2010. OE has used the device on several orders of joints during the month and recorded gluing times for a brush and the device. The data was collected from two clients gluing foam pieces with inner diameter of 1.5 inches and wall thickness of 1 inch. Timing started when the clients picked up a piece of foam for gluing and ended when the piece was put down to dry. Ten times were recorded for each method and client. The average times needed to apply glue to a single foam piece for two different clients are displayed in Figure 4. For the client with normal dexterity, it took an average of 37.8 seconds to brush glue to the foam piece. When the client used the device, the average time decreased to 11.1 seconds. The efficiency gains were even greater for a client with one paralyzed hand. This client took an average of 85.1 seconds with a brush and 13.2 seconds with the device. Mr. Gillis also remarked that the device required less training and quality control.

Clients at OE Enterprises have found a different swiping method than the one shown in the submitted video. Clients now start the swipe across the roller from the middle of the foam piece, spin the foam piece 180 degrees, and repeat. This prevents glue from getting on the front edge of the foam piece and reduces the number of joints rejected by quality control. Staff also reported that while the device applies a thinner, more even layer of glue to the foam, the 1/4” nap paint rollers absorb too much glue according to Armacell. As a result, OE has obtained special adhesive applying rollers from Armacell.

DISCUSSION, COSTS AND CONCLUSIONS

The Universally Accessible Contact Cement Applicator provides employees at OE Enterprises with a quick, easy, and safe way of applying contact cement to pieces of foam insulation. Replacing the former method of hand brushing, the device increases the accessibility of this employment opportunity. The adjustable glue scraper ensures that a desired amount of contact cement stays on the exposed part of the roller during use. Clean up of the device is made easy by the fact that the entire device can be disassembled and placed in lacquer thinner and then brushed clean. The cost of components for the final device is found in Table 1.

The most expensive component of our device was the HDPE used for the base, support walls, and glue trays. The total spent on HDPE was $95.38. Electronics (motor, power supply, switch, etc.) cost $33.65. Additional parts, such as metal rods and fasteners, put the total cost of one device $148.32.

One limitation of our device is that 100% coverage of the foam piece with contact cement may not occur on every swipe, especially with foam pieces of larger diameters. This is remedied with a second swipe across the roller, typically with the foam piece rotated 180 degrees. Another limitation is that glue trays are designed to hold only a limited amount of contact cement. While this conserves the amount of glue used and keeps the contents fresh, the trays must be refilled regularly.

In conclusion, we have created a device that is more effective at applying contact cement to foam pieces than using a brush. It is made from commercially available parts and can be manufactured in a typical machine shop with standard tools. We have received positive feedback from employees and supervisors at OE Enterprises who believe that the device enhances product quality and productivity and increases the vocational opportunities for clients with a wide range of disabilities. In particular, OE’s business development manager, Jamie Gillis, touted the device in the Triangle Business Journal (http://www.bizjournals.com/triangle/stories/2010/01/18/story11.html ).

ACKNOWLEDGEMENTS

We would like to thank Prof. Laurence Bohs for his design input, Steve Earp for his ideas and fabrication assistance, Daron Gunn and Matt Ball for their help throughout the design process, Prof. Rhett George for his assistance in our qualitative analysis, the management of OE Enterprises for all their support and our clients for their useful feedback. This project is supported by the National Science Foundation under Grant No. BES-0610534.