Repeatability of a Procedure for Measuring color contrast on products, including fitness equipment

Michelle R. Hoogwout1, BS, Harmony M. Hilderbrand2, BA,

Seanna L. Hurley2, MS, and Peter W. Axelson2, MSME

1Technical University of Delft, The Netherlands and

2Beneficial Designs, Inc., Minden, NV

Abstract

An ASTM standard has been drafted to increase access to mainstream fitness equipment by people of all abilities. This standard contains criteria for minimum color contrast for labeling and key components on fitness equipment to address the needs of people with a visual impairment. A contrast measurement procedure has been drafted for inclusion within this standard. Nine subjects completed a repeated measure design to determine if the measurement procedure is repeatable and inter-operator precise. The results indicate that the procedure is indeed repeatable and precise. This research will enable manufacturers of fitness equipment to determine, quickly and inexpensively, if their equipment has a sufficient contrast level. This measurement procedure can be adopted into other fields, which have to comply with ADA guidelines. This will substantially increase the accessibility of products and environments for people with visual impairments.

background

According to the National Institute of Healths National Eye Institute, over 4 million people over the age of 40 in the United States have a visual impairment (VI). The prevalence of VIs is expected to double in the next 30 years due to the aging baby-boomer generation (NIH, 2011). The ASTM F08.30 Fitness Products committee is currently drafting a standard for the universal design of fitness equipment (UDFE), which will include accessibility criteria for people with a VI. The Americans with Disabilities Act Accessibility Guidelines (ADAAG) defines a minimum contrast value of 70% in order to improve visual recognition by people with a VI (ADAAG, 2002). The draft ASTM UDFE standard uses this criterion for key equipment components. A method to determine the level of contrast has been under development (Hilderbrand, 2010). Spot meter technology has been shown to be a cost effective alternative to expensive equipment, used to measure specific attributes of detailed color elements. The intent of the contrast measurement and implementation of spot meter technology procedure is to enable fitness equipment manufacturers to perform simple measurements to determine the levels of contrast on their equipment. This will aid in designing universally accessible fitness equipment.

The contrast procedure implements the measurement of illuminance and luminance. The light that falls onto an object is known as illuminance and is measured in lux or foot-candles. Luminance refers to the light reflected off an object, or the perceived brightness of a surface. Luminance is measured in candela per square meter [cd/m2]. Both luminance and illuminance can be measured using a simple light meter, a technology that measures light within the visual spectrum.

Figure 1 demonstrates how contrast is a major issue for many people with VI. Products that have a range of colors may seem to be visually accessible. However, as shown in the control panel example, viewed through the eyes most people with VI, all of the colors appear as one similar value of gray. This has to do with the reflectance value of the colors displayed. Value has been identified as the property of color that the majority of people with VI can discern. The two control panels in Figure 1 are easy to discern when viewed in full color by a person without a VI. However, most people with a VI would have a much more difficult time discerning the color coding used in the left side console due to the lower contrast values as compared to the right side console. This same problem can be found in many products and signage found throughout different environments.

Purpose

The purpose of this study, a repeated measure design, was to test the repeatability and inter-operator precision of a new color contrast measurement procedure. Once the repeatability and inter-operator precision has been shown, this procedure can be adapted for use in other fields, allowing for manufacturers of products for both private and public usage to verify the visibility for people with a VI.

Method

Operators

Nine subjects, further referred to as operators, seven with testing and/or engineering experience and two without experience, performed the color contrast measurement procedure.

Instrumentation and Instruction

Operators were provided with a Sekonic L758CINE light meter, a standard 18% gray card, an X-Rite ColorChecker Classic color card, and instruction on the procedure and technology.

Set-up and Procedure

The test environment consisted of a windowless room with six overhead fluorescent light bulbs. The lights in the test environment were allowed to warm up at least 15 minutes prior to testing in order to ensure that the lighting level stabilized. It should be noted that lighting conditions are different within every environment. Prior to conducting the tests, the operators read the color contrast measurement procedure. Light meter operations were explained by the test administrator and any questions were answered. During each test, the door to the test environment was closed to control the amount of light. Operators were permitted to ask the test administrator questions during the test. The color card was mounted flush on the surface of a wall within approximately eye level of the operators; the top of the card was mounted at 1.68 m (66 in.). Each operator stood 1.02 m (40 in.) from the wall. Each operator checked the light levels by conducting illuminance measurements. These illuminance measurements were also used to check the calibration of the meter.

The operator then measured luminance of the lighter and darker surfaces (Figure 2). The contrast equation from the ADAAG was used to calculate contrast:

Contrast = [(L1-L2)/L1]*100% (1)

Luminance 1 (L1) is the luminance of the lighter area and Luminance 2 (L2) is the luminance of the darker area. The contrast level between the adjacent surfaces of L1 and L2 was calculated according to equation 1 and recorded as a percentage.

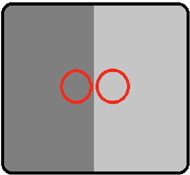

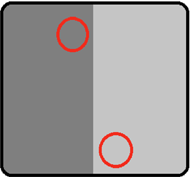

To get a proper measurement of both illuminance and luminance, the circle of the spot meter has to be fully contained within the objects surface. Readings should be taken at the same spot and readings should be adjacent to an edge of contrast (see Figure 3 and 4).

Aspects addressed in the draft standard that influence light include but are not limited to the test administrators clothes, type of light, angle of view, distance to the object, and light levels. These aspects should be kept constant during the entire measurement procedure.

Each operator (Oi) performed the measurement procedure on three different color pairs, calculating the resulting contrast for each color pair. Color contrast pairs test are as follows: Set A, Black and Bluish-Green; Set B, Blue and Yellow-; and Set C, White and Yellow. Each operator tested each color pair three times, resulting in a total of nine final contrast results per operator.

Data Analysis

|

Oi |

Level j |

|||||

Set A |

|

Set B |

|

Set C |

|

|

|

h |

k |

h |

k |

h |

k |

O1 |

-1.352 |

0 |

1.781 |

0 |

1.879 |

0 |

O2 |

0.575 |

1.564 |

0.675 |

0 |

0.037 |

0 |

O3 |

0.575 |

1.564 |

0.035 |

1.337 |

0.037 |

0 |

O4 |

1.412 |

0.000 |

-0.789 |

1.528 |

0.037 |

0 |

O5 |

-0.263 |

1.564 |

0.675 |

0 |

0.037 |

0 |

O6 |

-1.101 |

0 |

-1.247 |

0 |

-1.097 |

1.298 |

O7 |

0.973 |

0 |

-1.247 |

0 |

0.698 |

2.705 |

O8 |

-1.101 |

0 |

0.355 |

0.668 |

0.037 |

0 |

O9 |

0.282 |

1.290 |

-0.238 |

2.105 |

-1.664 |

0 |

Data was analyzed using the ASTM E691-11 standard (ASTM, 2011) to determine the repeatability and inter-operator precision of the color contrast measurement procedure. All equations and critical values used can be found in ASTM E69111.

REsults

The h value is the between-operator consistency statistic and k is the within-operator consistency statistic. A cutoff number that is referred to as the critical value of both h and k is used to detect outliers. For this experiment, the critical value of h is 2.23 and the critical value of k is 2.09. Both the h and k values calculated can be found in Table 1. Two statistical outliers were found, which are shaded in Table 1 (O7 Set C k 2.705, and O9 Set B k 2.105 are more than 2.09). The critical numbers represent a 0.5% significance level. The values found in Table 2 represent that there is a 99.5% chance that the values obtained with further testing will be within the boundaries given by r (repeatability) and RIO (inter-operator precision).

|

Set A |

Set B |

Set C |

Average contrast (%) |

85.727 |

72.498 |

35.290 |

Repeatability standard deviation |

0.499 |

0.584 |

0.889 |

Repeatability limit |

1.397 |

1.634 |

2.491 |

Inter-operator precision deviation |

0.675 |

0.849 |

1.382 |

Inter-operator precision limit |

1.889 |

2.378 |

3.870 |

The terms repeatability, standard deviation (within a laboratory) and repeatability limit are used as specified in ASTM Practice E 177 (ASTM, 2010). The inter-operator precision and precision limit were calculated using the inter-laboratory reproducibility calculations in ASTM Practice E691-11. The standard deviation and limits can be found in Table 2.

Discussion

The Sekonic L758CINE light meter calculates the lux and cd/m2 values from EV values, which results in a non-continuous scale and non-uniform increments. Although consistency statistics showed two statistical outliers, these outliers could analytically be explained due to the non-uniform increments and were therefore dismissed as analytical outliers.

The repeatability and inter-operator precision results found in this research indicate that this new procedure for measuring contrast is indeed repeatable and inter-operator precise given the conditions and limits of repeatability and inter-operator precision. Therefore, this new measurement procedure is valid for further use, and can be adopted within the draft ASTM UDFE Standard to enable fitness equipment manufacturers to verify their contrast levels. This will allow manufacturers to monitor and enhance their contrast levels, thus increasing usability of products by people with VI. This will be a great improvement for people with a VI, and their interaction with every day products.

Conclusion

Manufacturers of fitness and other equipment will be able to verify and improve the visibility and function of their products using this new procedure for measuring color contrast. Other potential applications for this measurement procedure will be for industries which mandate products to be considered accessible for persons with disabilities, through government regulations. Public and private facilities such as hospitals, airports, schools, grocery stores, fitness centers, and libraries will be able to determine if the signage posted within and around their facilities has sufficient contrast to be recognized and read by as many people as possible. This measurement method will allow for a notable change in accessibility for people with a VI.

Future research will need to be conducted with regard to reproducibility testing of the contrast measurement procedure. More research should be conducted on contrast measurements with real products as all the tests conducted so far have been implemented using a color card which is a standardized representation of colors that might be used on various pieces of fitness equipment. The procedure should also be tested by people with a VI, in order to validate that the contrast criteria is adequately meeting the needs for VI access. The influence of gloss finishing on contrast levels should also be investigated. Another point of interest is outdoor lighting conditions and their influence on contrast levels. It is expected that this contrast measurement procedure will be implemented for use in the draft ASTM UDFE Standard. It is also expected that the measurement procedure could be applied to many other types of products and signage in other types of environments.References

ASTM. (2010). Standard Practice for Use of the Terms Precision and Bias in ASTM Test Methods (E177-10). West Conshohocken, PA: ASTM International, 2011, DOI: 10.1520/ E0177-10 , www.astm.org

ASTM. (2011). Standard Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method (E691-11). West Conshohocken, PA: ASTM International, 2011, DOI: 10.1520/E0691-11, www.astm.org

American with Disabilities Act Accessibility Guidelines (ADAAG), (2002), Clause A4.30.4, Retrieved November 23, 2012 http://www.access-board.gov/adaag/html/ adaag.htm#A4.30.5

Hilderbrand, H., Hurley, S.L., Axelson, P.W. (2010). Measuring Luminance Color Contrast on Products, Including Fitness Equipment, for People with Visual Impairments. Proceedings of the RESNA 2010 Annual Conference. Las Vegas, NV: RESNA Press.

The National Institutes of Health (NIH), National Eye Institute, (2011). Retrieved January 02, 2013, from http://www.nei.nih.gov/eyedata/ vision_impaired.asp#4_