ABSTRACT

A Smart Wheelchair Component System has been developed to assist in obstacle avoidance. The system's modular design does not require major alterations to the wheelchair. The system allows a wheelchair to approach within 10.4 cm of an object while preventing collisions. During autonomous wheelchair movement, the system experienced seven collisions in 91.5 hours of testing.

BACKGROUND

Some individuals find it difficult or impossible to operate a standard power wheelchair (1). To accommodate this population, several researchers have developed "smart wheelchairs" which can detect objects in the environment and assist with obstacle avoidance and safe navigation (2). Most smart wheelchairs require considerable modifications to the underlying wheelchair. Others will only operate in specially modified environments (3).

STATEMENT OF THE PROBLEM

A smart wheelchair system which requires substantial modification to the wheelchair will be impractical for installation in many seating clinics, will interfere with normal service of the wheelchair, and may limit clients' ability to obtain navigation assistance features while also receiving a wheelchair which meets their needs for specialty seating and other features. Therefore, it is desirable to develop a modular smart wheelchair component system which can be added to a variety of commercial power wheelchairs with minimal modification.

Design

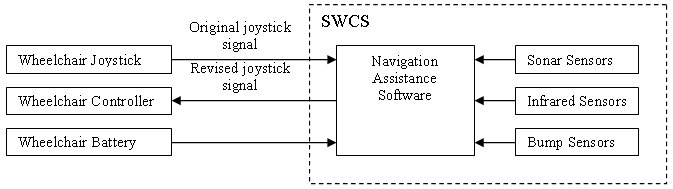

A modular smart wheelchair component system (SWCS) has been developed which is compatible with a variety of wheelchair models (Figure 1). Design was based on the following criteria:

- Preserve the user's safety;

- Preserve the user's independence: The SWCS respects the user's input and follows the normal joystick signal as closely as possible while avoiding collisions.

- Modular design: The SWCS consists of a central electronics module and a set of sensor modules. The number and placement of sensor modules can vary based on the wheelchair and the individual client's needs. The electronics module is designed to connect to a wheelchair's joystick with minimal modification of the chair.

|

The SWCS is designed to receive and send joystick information by connecting to an existing alternative control interface. It has been tested with the Universal Specialty Controls Module (USCM, Penny & Giles, Cwmfelinfach, Gwent, UK), compatible with Permobil, Sunrise, and Jazzy wheelchairs, and the Digital Drive Box (Invacare, Elyria, OH). A stand-alone joystick plugs into the SWCS, which in turn plugs into the control module (USCM or Digital Drive Box). The SWCS reads the joystick signal and sends a revised joystick signal to the control module (Figure 2). Under most circumstances, the revised joystick signal is identical to the original signal.

|

If an obstacle is detected, the SWCS alters the joystick signal to avoid collisions. The navigation assistance software uses a case-based decision method similar to that used in some mobile robotics applications. The software then uses the joystick and sensor information to assess the risk of various "cases" such as driving forward into an obstacle, backing into an obstacle, or turning left into an obstacle. If necessary, the software takes actions to avoid a collision. Possible actions include slowing down, turning away from the obstacle, and stopping the wheelchair.

DEVELOPMENT

The navigation assistance software was written in Visual C++ (Microsoft, Redmond, WA) and runs on a laptop computer (Gateway 2000, Gateway, San Diego, CA). Data is obtained from the wheelchair joystick and sensors and sent to the wheelchair controller using two data acquisition cards (DAQCard 1200 and DAQCard 6024-E, National Instruments, Austin, TX).

The SWCS uses nine sensor modules, each of which includes one sonar sensor (Sonaswitch, EDP Company, Livonia, MI) and one infrared sensor (GP2D12, Sharp Instruments, Mahwah, NJ). These sensors were selected in order to detect a variety of obstacles at distances of interest for wheelchair navigation, and to reduce the cost of the overall product (4). An additional infrared sensor was mounted on the wheelchair footrest to detect drop-offs such as curbs or descending stairwells.

EVALUATION

The SWCS has been tested with two wheelchair models (Action Arrow, Invacare, Elyria, OH; Quickie S-626, Sunrise, Carlsbad, CA). Five performance goals were identified (Table 1). These criteria address the ability of the system to prevent collisions without interfering with the user's ability to travel through doorways and narrow hallways, or pull up to furniture (docking). An iterative cycle of testing and software adjustment was performed until the system was able to meet each criterion on three successive attempts while avoiding collisions. For these tests, the wheelchair was operated by an individual who does not have a disability. The final results are shown in the two right-most columns of Table 1.

Reliability tests were performed in which the wheelchair traveled at random under the control of the computer. The wheelchair moved within an enclosed area (4.5 m x 4.3 m) containing six obstacles (45 cm x 45 cm x 1 m each). For each wheelchair, system failures (other than collisions) were recorded for an initial observation period, during which the software was adjusted to reduce the risk of collisions. Both collisions and system failures were recorded for a final observation period, during which the software was not adjusted. For the Quickie S-626, eight system failures were observed during 74 hours of total testing and four collisions were observed during 35.5 hours of observation with the final software configuration. For the Arrow, one system failure was observed during 60 hours of total testing, and three collisions were observed during 56 hours of observation with the final software configuration.

DISCUSSION

The results in Table 1 indicate that the SWCS will allow a wheelchair to maneuver close to objects in the environment while preventing collisions. During random movement, seven collisions were observed in 91.5 hours of testing, or one collision every 13.1 hours. Ideally the wheelchair will experience no collisions; however, there will always be some obstacles which the sensors are not capable of detecting. Some of these collisions could be avoided by including more sensors; however, complete sensor coverage may be impractical in terms of the cost of the final system. Future work will investigate levels of sensor coverage which balance safety and affordability.

In addition to collisions, nine system failures were observed during 134 hours of testing. These failures were traced to wiring or the computer operating system, rather than the navigation software. Future work will include developing a more robust electrical system and implementing the software on a microprocessor rather than a laptop computer.

The evaluation indicates that the SWCS can provide effective navigation assistance for people who have difficulty driving existing power wheelchairs. The modular approach provides flexibility in moving the system to any wheelchair that otherwise meets the client's needs, and in customizing the system to the individual client's strengths and limitations. Further testing will be conducted on two additional wheelchair models (Entra, Permobil, Sweden; Solaire, Everest and Jennings, Atlanta, GA). One drawback of this analysis is that the chair was tested by a driver without a disability. Future testing will include subjects with disabilities.

References

- Fehr L, Langbein W, Skaar S. (2000). Adequacy of Power Wheelchair Control Interfaces for Persons with Severe Disabilities: a Clinical Survey. Journal of Rehabilitation Research and Development. 37(3):353-60.

- Levine S, Bell D, Jaros L, Simpson R, Koren Y, Borenstein J. (1999). The NavChair Assistive Wheelchair Navigation System. IEEE Trans on Rehab Eng. 7(4):443-451.

- Yoder J, Baumbartner E, Skaar S. (1996). Initial Results in the Development of a Guidance System for a Powered Wheelchair. IEEE Tran on Rehab Eng. 4(3):143-151.

- LoPresti EF, Simpson RC, Miller D, Nourbakhsh I. (2002). Evaluation of Sensors for a Smart Wheelchair. Proceedings of the RESNA 2002 Annual Conference. pp. 166-168.

Acknowledgments

The work is supported by the National Institutes of Health (#1R43HD040023-01A1).

Edmund LoPresti

AT Sciences, 4705 Fifth Ave. 1-I,

Pittsburgh, PA 15213

412-901-1042,

412-383-6597 (fax),

edlopresti@acm.org