ABSTRACT

Our client is a nine-year-old boy with VATER association who likes to play baseball. He was born with a shortened radius, and his index finger was surgically moved to replace his missing thumb. His right arm and hand have approximately one-half the strength of the left side. The gloves that he used previously limited his playing ability because they were either too small or too hard to close. We have created an adapted baseball glove that is easier to close and relatively lightweight. This was accomplished by modifying the commercially available Wilson EZ-Catch glove, adding a V-flex notch, extending the Velcro strap, and including an aluminum extension for his thumb. The glove improves our client's ability to catch, while having a normal appearance.

BACKGROUND

VATER stands for vertebrae, anal, trachea, esophagus, and radius/renal. This is a family of defects often used for diagnosis [1]. A patient that exhibits more than two of the problems is considered to have VATER association. The problem affecting our client is a shortened radius and missing thumb. The result is that his wrist is not well supported by his bones, and his right arm and hand have approximately half the strength of his left side. His hands are also relatively small.

Our client, who currently plays right field, was able to close his old glove well, but the glove was considerably smaller (10") than typical little-league gloves. However, he was not able to close his newest glove, which was the same model in a larger size (11"). Our client showed difficulty in aptly handling a glove in which his hand was too small. This led to a serious disadvantage in playing baseball.

Our client therefore needed a glove that was easy to close and lightweight, with a catching area comparable to that of larger sized gloves. Commercially available gloves did not fill this need for two reasons: (1) left-hand-thrower gloves are not necessarily available in all models, and (2) gloves become more difficult to close as their size increases.

Problem STATEMENT

The goal of this project was to design and create a baseball glove that our client could easily use. It must be light enough to be held by his right hand, easy to close, and have an effective catching area comparable to gloves of his peers. It should look like a commercial glove and not have any adaptations that would give him advantages over other gloves.

Rationale

Without the ability to use a glove properly, our client might have had to quit baseball. His smaller glove provided some ability to catch, but as each year becomes more competitive, his standing in the top third of his teammates may decline. The larger glove served its purpose for grounders, but for catching fly balls, our client had difficulty closing the glove and often dropped the ball even when it fell directly into the glove. We provided a glove that allowed our client to remain competitive.

Design and Development

|

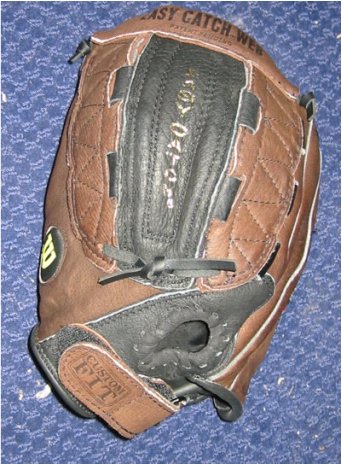

We incorporated the V-flex design of Mizuno youth gloves into the base glove, using a slightly different cut, as shown in the lower left of Figure 1. Since our client closed the glove in a certain way due to his hand, we found that a cut at his natural hinge was optimal for increasing flexibility. Our client's hand was relatively small, and the existing Velcro strap did not close the glove enough to secure his hand. Thus, an additional piece of Velcro was attached to the glove to allow tighter binding of the Velcro strap. This can be seen in the back view of the glove (Figure 2). Finally, we wished to make the glove fit our client's smaller hand better.

|

At each stage of the glove production, we met with our client for feedback, which typically involved playing catch with him in his backyard. Our client's parents were also especially helpful in answering questions. Our client also had a wrist brace, which was made for him by his occupational therapist. Though the brace helped support his wrist, our client did not like to wear it, so we sought a design that would not require its use.

|

Evaluation

During various stages of our project, our client often changed his mind about the efficacy of the aspects of the glove we were testing. Thus, the most objective evaluation was done experimentally, by playing catch with our client. We found that with our new glove, our client was able to make one-handed catches, which he could not do with either of his previous gloves. His ability to close the glove is markedly improved, and he likes the look and feel of the glove.

Discussion and Conclusions

The glove works as anticipated, but there are some limitations. Our client is still growing and we cannot predict how his strength and size will change over the next few years. Ideally, his hand strength will increase to the point that he can use a commercial glove without modifications. We considered modifying our glove to make it larger, as the Wilson EZ-Catch is only available up to a 10.5" size. However, adding a piece to the top to increase the size would hinder flexibility and add weight. Most importantly, our client felt that the glove's current size was perfect.

It was also difficult to obtain this particular glove for the right hand; we had to communicate with several vendors and wait several weeks in order to obtain two gloves. The glove also comes in slightly different models, as we discovered. The type that worked best for our purposes was model #A0427EZ105. Sewing of the glove modifications was done by hand because a machine was unable to reach particular parts of the glove.

The glove maximizes catching area by allowing the catching area to bulge outward. This increases surface area and maximizes the impact time for catching. Thus, the size of this area is more important than the other dimensions of the glove. The thumb extension, besides increasing leverage, also seems to help in stabilizing the thumb area. With this adaptation and our additional modifications, our client can successfully catch and play with his new baseball glove.

REFERENCES

[1] "The VATER Connection Information Sheet." The Vater Connection. <http://www.vaterconnection.com/faq.htm"> Revised 28 September 2001. Accessed 7 September 2002.

Acknowledgements

Thanks to Dr. Larry Bohs for creating this opportunity and for his continued support and teaching throughout the semester. We would also like to thank our client and his parents for their cooperation and invaluable input in the glove design. Finally, we would like to acknowledge Robbin Newton, our client's occupational therapist, for submitting the project and getting us started.