Toy Retriever

Abstract

People with spinal cord injuries at C-7 and T-1 have dexterity problems with their hands and fingers. Our client has an injury at C-7 of his spinal cord. Due to his injury, he is paralyzed below the chest and uses a wheelchair for mobility. His requirement was to have a device that would enable him to independently fetch toys off the floor from his wheelchair. We built a device that consisted of a scooper and blocker that allowed him to retrieve objects from the floor with minimal effort in a safe manner. The device, which is powered by a +6V battery, can be lowered to the floor using a switch. Once lowered it can scoop the toy and lift it up using another switch.

Background and Problem Statement

Our client is 2-year-old boy with a C-7 spinal cord injury. He is paralyzed below the chest, and has good arm strength but poor hand grip. He has normal cognition and uses a manual wheelchair for mobility. The client's family requested a device that would help him fetch toys off the floor from his wheelchair. Commercial grabbers and reachers are used by people to fetch a range of objects, but these devices require strong grip and a good amount of arm strength. It is also difficult to use these devices to fetch flat objects. Thus our client's condition and needs make it extremely difficult to use commercially available devices successfully. The goal of this project was to build a device, which would be lightweight and attach to the client's wheelchair. The device would be operated completely on batteries making it easy to use. Also, it would be safe, with the motor and electronics isolated from the client.

Design and Development

Project Specifications and Possible Solutions:

On our first visit to the client's home, we looked into aspects that would help in our design process, such as the client's strength, his accessibility to the device, the average size of the toy he would pick up and his cognitive skills. Initially, we considered several possible solutions. One solution was to attach Velcro or magnets to the grabbing device and the toys. However, the child would not have the strength to separate the toy from the grabbing device. Another one was a vacuum/suction idea, but that was abandoned due to safety concerns. We then came up with the idea of two shovels coming together to scoop the toy. This led us to the `Scooper and Blocker' design.

|

Scooper and Blocker Design:

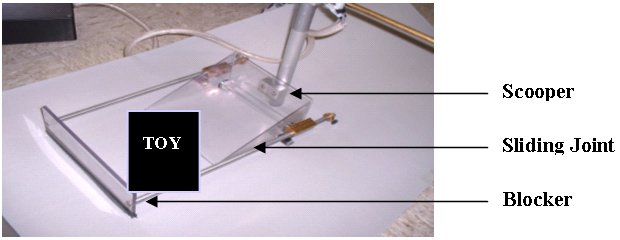

The scooper and blocker unit was designed keeping in mind the usual toys that the client would pick up. The unit is attached to the wheelchair and can be raised or lowered to the ground under switch control. This allows the client to position the device so that the desired toy is located between the scooper and blocker (Figure 1). As the client pushes his wheelchair forward, the scooper moves under the toy and the blocker stays in place. The scooper has wheels so that is slides easily, whereas the blocker has a sticky, diamond mesh lining on its bottom causing it to adhere to the floor. Both the scooper and the blocker are made of strong, lightweight Lexan.

Raising and lowering the device:

We first investigated a manual system to raise and lower the device, but since the client does not have enough strength, we settled on one that would be motorized. We investigated several methods, which included a worm gear arrangement and a hydraulic piston arrangement. We finally decided to use a motorized automobile antenna mechanism that would raise the scooper and blocker unit from the ground.

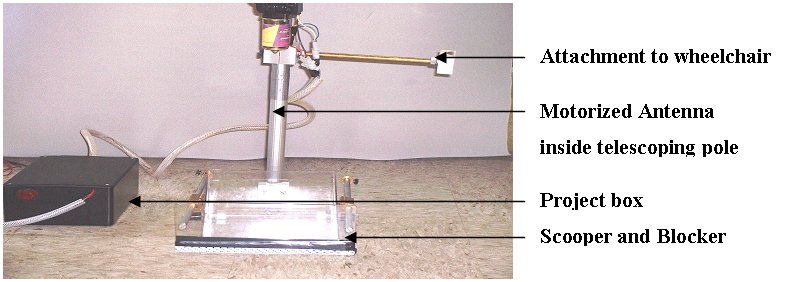

Initial experimentation with the antenna system showed that it was flimsy. A telescoping pole assembly surrounding the antenna provided the rigidity (Figure 2). The telescoping pole was cut to the proper dimensions and a 0.125" slot was cut along the side of the telescoping pole, running from the top to the base. A setscrew was attached to the antenna and aligned so that it was held within the slot. Thus as the antenna was retracted or extended, the setscrew prevented any unwanted rotations.

The existing circuit for the antenna was studied and modifications were made to suit our needs. The primary source of power for the device is a +6V rechargeable battery. This is fed to a +5V voltage regulator and the antenna draws power from the +5V-regulated supply. Switches are used to lower and raise the scooper and blocker unit. When the unit reaches its upper or lower limit, the antenna motor draws higher current, which trips a current limiter (re-settable fuse), and shuts off the antenna motor. The battery and circuit are enclosed in a project box (Figure 2), completely isolated for safety. The parents of the client would have to recharge the battery regularly.

Integrating the various components:

The antenna is connected to the wheelchair rod and the scooper and blocker unit with a clamp that can be easily attached and detached. (Figure 2)

|

EVALUATION

The initial device evaluation consisted of a presentation to an audience of occupational therapists, physical therapists, speech-language pathologists, and biomedical engineers. A demonstration followed after which people provided feedback and suggestions. One of the concerns was the kind of switches that could be used by the client with ease for operating the device. This was addressed by giving the client the option to select any commercial switches, which plug into a standard 1/8" audio jack. Another concern was the safety issue, which is addressed by enclosing all wires, battery and circuits, thus isolating them.

DISCUSSION AND CONCLUSIONS

The device can be lowered and raised, and in many situations, it can scoop the toy as desired. However, it does not work consistently with all toys and on all surfaces. Possible improvements include: a better attachment to the wheelchair for more stability; and a stronger motor to lift heavier toys.

Minor modifications are needed in the electronic circuitry to make the device completely safe and user friendly. The attachment of the project box to the wheelchair needs to be addressed. Future work could also involve making the device foldable.

ACKNOWLEDGEMENTS

Funding was provided by NSF Grant BES-9981867 and the UNC Ueltchi Service Learning Grant. The authors also wish to thank Richard Goldberg, the chief advisor in this project, along with Kevin Caves, Lilie Bonzani, the client and his family and the Physics Shop for their assistance in design and development of this device.

CONTACT INFORMATION

Punita

Christopher

152 McNider Hall, CB 7575

Department of Biomedical Engineering

University of North Carolina

Chapel Hill, NC, 27599

Email: pchris@bme.unc.edu