ABSTRACT

The client is a six-year-old boy exhibiting symptoms of autism and manic depression. These symptoms manifest in his desire to constantly pour liquids and granular objects. He will pour for as many hours as allowed, but the mess produced, lack of supervision, and inclement weather when he pours outdoors, among other restrictions, prevent him from always performing this important activity. The Pouring Palace is a large structure that incorporates different activities that involve pouring granular objects such as rice or beans. These activities include a cranking and lifting mechanism that hoists the material above the structure and pours it over objects that the client will configure to a pegboard, a magnetic board for him to affix objects over which to pour, and various bins to hold the material for him to create pouring activities with his own imagination.

BACKGROUND

The client has an obsessive desire to pour any heavy and fast flowing material for as many hours as his parents, schoolteachers, and occupational therapist allow him during the day. This pouring action soothes him. However, he also has a tendency to function with extreme movements such as flinging objects, punching others, airborne flipping, and running into walls. At home, the client's family has provided him with an outdoor environment where he can use water from a hose to pour over dirt, rocks, and buckets. If he flings objects, it will not make a mess, hurt other people, or damage anything valuable as if it were indoors. However, this makes him constantly dirty and wet, causing him to be prone to infection, wastes water, and is not appropriate in cold weather. Because of his disabilities, the client's critical-thinking and problem-solving skills are underdeveloped. He has trouble realizing cause-and-effect relationships and learning his own visual-to-motor interaction.

PROBLEM STATEMENT

The goal of this project is to build a device that will help satisfy the client's pouring need, while providing him with several new activities that will challenge and develop his cognitive skills. The device should be usable indoors with a granular material such as rice or beans. In addition, it should contain the material so that cleanup is easy, be safe for him to use unsupervised, and allow him to pour for long periods of time.

By providing the client with this pouring device, three goals will be met. First, he will have an environment in which he can pour for as long as he wants whenever he wants. Second, by arranging the toys in different configurations, figuring out how to use the cranking and lifting mechanism, and using his imagination, the client will develop critical-thinking and problem-solving skills. Third, making the device easily cleanable and possible for him to use unsupervised will relieve time and emotional stresses incurred by the family.DeSign and Development

I observed the client in his home environment playing with his outdoor waterfall setup, as well as during his occupational therapy sessions, to cooperatively asses his needs with his family and his therapist. They have previously provided him with a range of activities involving pouring, such as a baby pool filled with sand and toys. Most commercial products they have tried leak, do not keep his attention, or break when subjected to his energies.

|

|

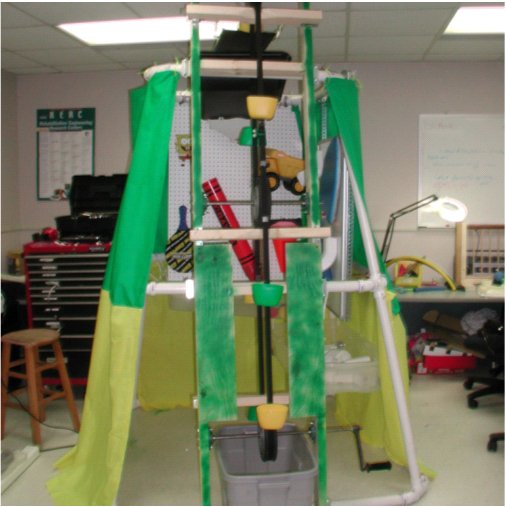

A photograph of the completed Pouring Palace is shown in Figure 1. Design of the structure focused on stability and ability to affix objects to the frame. The frame was constructed from PVC tubing and connectors for rigidity and light weight. The truncated-pyramid shape of the completed frame provided a stable structure due to the low center of gravity compared to a rectangular structure. The pyramid shape consisted of a 5-foot square bottom, 4-foot square middle rung, and 3-foot square top rung, each separated by 3 feet vertically.

Several components affixed to the PVC frame that allow different pouring activities. The first, shown in Figure 2, is the lifting and cranking mechanism that scoops the rice (or other granular material) in the following manner. A wooden frame shaped like a ladder supports three 1/2" diameter axles that are mounted to the wooden frame with self-aligning flange bearings. 9" diameter wheels are affixed to each of the axles. The bottom axle extends beyond the width of the frame and has a bicycle crank-arm attached with a handle, modified from a bicycle pedal. Cranking this handle rotates a belt attached to the wheels. The belt consists of two 1" wide, 8' long woven nylon straps, attached together using their metal loop-through buckles. Eight colorful plastic cups, bolted to the belt, scoop into a bin filled with rice as the handle is turned. The rice is lifted the length of the frame and as it reaches the top, drops into an elevated bin that directs the rice to the pegboard, as described below.

During the design process, we asked the client to try the cranking mechanism. His quick and forceful rotation of the crank quickly spotlighted the flaws of the initial design. If a cup twisted axially at high speeds, the belt would derail. Therefore, two mechanisms were put in place to eliminate derailment and twisting. First, wooden guides were affixed to the frame to direct the cup and belt directly over the wheels to prevent derailment. Second, Velcro strips were sewn onto the belt ends to prevent it from loosening due to vibration. This allowed a high tension to be applied to the belt, preventing twisting.

The second component of the device is the pegboard. The client can easily attach toys or other objects to this pegboard with standard hooks. The cranking and lifting mechanism drops the rice from above over the objects affixed to the pegboard. Below the pegboard is a shallow bin that collects the falling rice and creates a waist-high surface for the client to contain rice. A tub connected to one end of the bin dumps rice to another bin that hangs below the magnetic board, the next component.

The magnetic board is affixed on the adjacent side of the frame. It allows the client to configure tubing and funnels (with magnets attached) freely, to make pathways for rice to flow. The bin attached below collects rice. Because it hangs lower than the bin beneath the pegboard, it provides him with an alternate position on which to play.

Fabric strung from the rungs of the frame surrounds the entire structure. This prevents rice from bouncing or being flung outside the frame, and also creates a more aesthetic tent-like playing area.

Evaluation

It will take months to evaluate the success of this device in teaching the client problem-solving and critical-thinking skills; however, the structural success has been evaluated. He can operate the lifting mechanism at his maximum rotational speed without derailing the belt. He can also mount as many toys as he pleases to the magnetic board and the pegboard without putting undue stress on the frame. He can fill the bins to the brim with rice without causing undue stress on the frame. The tent also contains the rice, making cleanup easy.

Discussion and Conclusions

The Pouring Palace will provide the client with an environment to occupy himself with his favorite activity safely, cleanly, and independently. The different levels of complexity with each component will provide a range of activities that he can both use immediately and learn with time, imagination, and investigation. Also, his family will be provided with more freedom, as he will be able to operate the device independently. Any toy can be mounted to the pegboard, by attaching a hook, or attached to the magnetic board, by gluing on a magnet. One drawback of the device is that is relatively immobile. Once it is assembled, disassembling it is difficult. Fortunately, the client's family has provided sufficient garage space for the Pouring Palace to reside. Future work could involve adding more tubing mounted to the frame through which the client could pour materials, or adding valves to the ends of the tubes so that he can build up larger quantities of rice before pouring. The Pouring Palace will allow the client to continually entertain himself, learn new things, and reduce care-giving stress.

Acknowledgements

I would like to thank my professor Dr. Larry Bohs for teaching the philosophy of good design and for exhibiting that philosophy himself, Mark Palmeri, teaching assistant, aided in helping me clean up the incessant mess created by flying rice. I'd also like to acknowledge Jodi Petry, the client's occupational therapist, for pointing me in the right direction, and Joe Owen, machinist, for helping me with various aspects of the lifting mechanism.