PAPER CUTTING DEVICE TO AID INDIVIDUALS WITH LIMITED HAND COORDINATION

ABSTRACT

Many children with athetoid cerebral palsy, including our five-year old client, have difficulty cutting paper independently. The goal of this work was to design a device to allow individuals with limited hand coordination to safely and autonomously cut paper. The resulting device consists of a paper holding fixture and a pair of mounted electric scissors. Each device met the design requirements to be safe, aesthetic, durable, portable, and nonrestrictive. This device will help a child to complete class assignments involving cutting paper and will provide hours of fun while boosting self-esteem.

BACKGROUND

Our client is a five-year-old girl with athetoid cerebral palsy who desired a method of cutting paper autonomously. Athetoid cerebral palsy limits her muscle tone to make reaching, grasping and other skills requiring coordinated movements difficult. In the past, our client required someone to hold the paper, as well as stabilize a pair of pushdown tabletop scissors, so she could cut. Even with such help, great effort was required to make simple cuts. She needed a device to hold the paper in a position to be cut, and also a less strenuous and more stable method of cutting compared to the manual scissors.

PROBLEM STATEMENT

Currently, there are no commercial devices to aid individuals with limited hand coordination to cut paper autonomously. To increase our client's sense of autonomy and confidence, our device must permit self-insertion of paper, independent cutting, and require minimal physical exertion. The device must be portable and aesthetically pleasing to minimize any self-consciousness generated by its use.

RATIONALE

Our client cannot currently participate in many activities in her kindergarten class without help. The paper cutting aid will provide her with an activity that she can perform independently, allowing her to gain confidence. Our client would be able to load paper of her choosing into the paper-clamping device and secure it. Then using the automatic cutting device, she could safely cut the paper in a desired shape and easily remove it from the paper-clamping device. The process of independently loading, securing, and cutting the paper would allow our client to cut paper autonomously in class and at home. Cutting out snowflakes, paper-dolls, or basic shapes would permit her to complete class assignments without the aid of a parent or assistant. Therapeutic gain and further cognitive development could be obtained from this process.

DESIGN AND DEVELOPMENT

We regularly met with our client, her mother,

and her occupational therapist to ascertain our client's needs and test the

limits of our client's hand coordination, range of motion, and favored gripping

posture. We found that our client had only moderate difficulty with smooth

vertical motions and was most comfortable working with her arm mostly extended.

Our client also showed no difficulty in gripping objects except when adjusting

objects in her hands. From analyzing her strengths and limitations, we decided

to exploit lateral movements and to support her arm on a resting surface for

minimal fatigue.

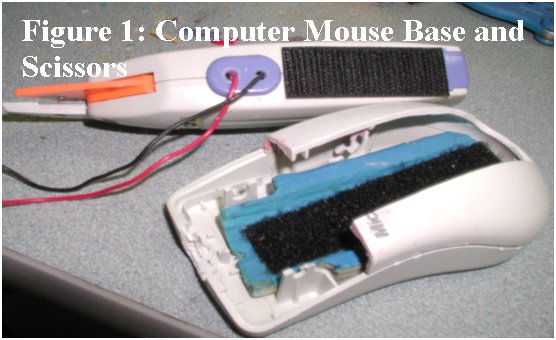

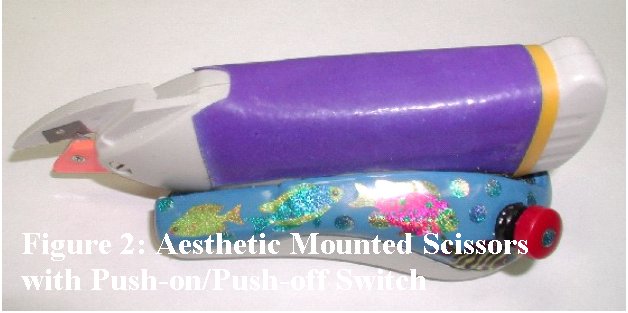

We bolted the Vise-Grip to an aluminum block at an angle that would hold the paper 1 cm above the desk, and mounted this apparatus in a blue plastic enclosure covered with colorful stickers. Rubber feet were attached to prevent the enclosure from resting on the Vise-Grip mouth, and to add stability to the fixture. During client testing, the release lever of the Vise-Grips proved difficult to reach due to its small size and location. As seen in Figure 3, we bolted a wider polypropylene grip extension piece to the vise-grip release lever, making it easy to actuate by our client.

EVALUATION

During device testing with our client, we found that the mounted scissors were easy to use and that our client could readily load and unload paper. She experienced some difficulty in cutting the corrugated part of a piece of paper until she learned to reposition the paper with the clamp mouth and use her free hand to guide the paper into the scissors. When our client tried to cut several pieces of paper at once, she could only cut four pieces without getting the scissors jammed. She was adept at using the scissors to cut thin cardboard and construction paper; however; she jammed the scissors when trying to cut a piece of paper that had been folded in order to allow a snowflake to be made. She quickly learned the rate needed to move the scissors to prevent a paper-jam and how to remove a paper-jam. Our client learned how to center the piece of paper in the mouth of the paper clamp before closing the clamp mouth and how to position the scissors to cut the suspended paper. Our client required minimal practice to learn to cut paper independently using the device.

DISCUSSION AND CONCLUSIONS

Our device's major advantage is the ease of loading and unloading paper in the clamping mechanism by our client. The electric mounted scissors also allow for more cutting autonomy. The electric scissors can be turned on easily and remain on as our client cuts by sliding the mounted scissors. One disadvantage, the motor noise, is inherent and unavoidable. A second disadvantage is impact durability but the risk of dropping the device is low because our client's wheelchair desk and school desk have raised edges. The mounted scissors and paper-clamping device are durable, safe, aesthetic, and portable. The final device met all objectives, and will help improve our client's independence at home and school.

ACKNOWLEDGEMENTS

We would like to thank Dr. Larry Bohs, our professor, for permitting us to have this design opportunity and aiding us in the design and manufacturing process. Our client's Occupational Therapist, Robbin Newton, was very helpful in consulting with us and providing numerous materials for experimentation. We also greatly appreciate the time donated by machinists Joe Owen and John Goodfellow, who milled the enclosure and aluminum block that secures the vise-grip clamp.