DEVELOPMENT OF A STICKER DISPENSER TO ASSIST THOSE WITH LIMITED DEXTERITY

ABSTRACT

A student design team known as the UMR Sticker Solutions Team has completed a class project to assist the workers at the Rolla (Missouri) Area Sheltered Workshop in completing their task of removing stickers from a roll and placing them on unfilled product bags. These stickers are commonly price or rebate stickers that are affixed to charcoal or pet food bags. The Workshop employs persons with disabilities and jobs involving sticker affixation compromise a large portion of the available positions. However, for persons with limited dexterity the problem of removing the sticker from its wax-coated backing material is quite difficult and causes much frustration to the employees. To remedy this problem and assist the employees in this task, the design team collected the customers' (in this case the management and employees at the Workshop) desires for an assistive device, designed various concepts, selected the most suitable concept, manufactured two prototypes and delivered them to the workshop. The customers were very satisfied with the prototypes and the device has eased the most difficult step in the labeling process.

KEYWORDS

Sticker dispensers, assistive products, design methods

BACKGROUND

Students from the Modern Product Design Class at the University of Missouri – Rolla were assigned projects to develop assistive products for the workers of the Rolla Area Sheltered Workshop. The Rolla Area Sheltered Workshop employs approximately 30 workers with a variety of disabilities, in several jobs. The jobs at the Workshop involve a variety of skills from counting and packing boxes to "envelope-stuffing." The authors of this paper were assigned to develop a product to assist the workers in the job of removing promotional stickers for placement on empty bags.

The worker's tasks for this job are described below:

Customer Need |

Weight |

|---|---|

Reduce the complexity of removing the sticker |

5 |

Radically changes the workers' task |

1 |

Reduces the time necessary to remove the sticker |

5 |

Easy to store when not in use |

1 |

Ambidextrous use |

5 |

Ability to use with a single appendage |

5 |

Quiet operation |

3 |

Safety, no exposure of internal components |

5 |

Proper waste disposal |

3 |

Ability to operate on AC power |

3 |

Ease of set-up |

2 |

Exhibits a small footprint |

2 |

Can operate with a range of sticker sizes |

5 |

Can operate with different sticker thicknesses |

5 |

Can operate with different roll sizes |

5 |

The worker gets a bag from the stack. He arranges the bag so that the side where the sticker is supposed to be stuck is facing up. He peels the sticker off the backing paper and sticks it on the bag at the desired location. He then stacks the bag into a finished stack. The supervisor then takes the stacks and leaves them on the pallet to be transferred.

Many of the workers have limited dexterity in their hands and fingers. These workers have trouble removing the sticker from the backing paper. The management of the Workshop does not want any device that will place the sticker on the bag for the worker. By allowing more of their workers to successfully remove the sticker from the backing paper, they will expand the number of workers able to perform the job well, with this being their overall goal.

DESIGN QUESTION

The first part of the project was to get to know exactly as to what the customer wanted. The authors used different customer need acquisition tools and came up with an organized table depicting the customer needs and their importance. The weights in the Table 1 below were allotted to each customer need on a scale of 1 through 5, one being the least important and 5 the most important.

It can be easily understood from the above table that the product should reduce the complexity of removing the stickers. Secondly, the customers needed a product which shall be very safe for the worker handling it and should be versatile. They also did not want to automate the process completely as it would make the workers' job too easy and thus may hurt his/her self esteem.

|

|---|

Products similar to the customer desires are available for purchase; however, the products available in the market are not very safe in operation for a person having limited dexterity. The existing products have many exposed moving parts and also have many unprotected sharp corners. Many of these devices cost over $500. An example of one of these commercially available dispensers can be seen in Photo 1. In this product there is an exposed rotating abrasive drum and an exposed knife-edge near the location where the sticker is dispensed. Thus, the challenge of the project lay in the fact that, keeping all the customer requirements in mind, the authors had to develop a sticker dispenser so that it would be very safe, easy to operate and affordable.

METHOD

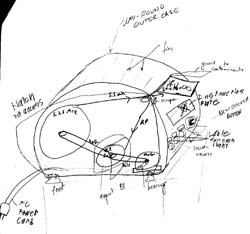

In order to completely satisfy the customers' expectations in the product, the authors developed over thirty separate concept variants using various design methods (1) and selected the most adequate concept through the use of a novel concept selection tool that the authors designed. This selection tool ensures that the selected concept is the best concept in terms of satisfying the customers' needs by linking these needs to a functional representation (2) of the product, which was shared by all of the concept variants. This tool awards each concept variant a score between zero and one, where a value of one would mean that the concept completely satisfies all of the customer needs. In the end, the concept variant that the authors chose to develop garnered a score of .942. The results of a Pugh-chart analysis also showed this concept as the most suitable. The initial sketch of this concept variant can be seen in Photo 2. The concept was developed using the C-Sketch method (1) in which each team member worked on the concept for a short period of time before passing it along to another team member to modify it. This hectic method of concept generation is evident in the sketch.

|

|---|

This concept scored very high in the concept selection tool because of the high degree of safety in its rounded case and completely enclosed electronics and mechanical components. It also scored very well in “ease of use” category because of the optical sensor; the concept has an “automatic” sticker feed in that it senses when a sticker has been removed and it will then export the next sticker. Furthermore, the concept also scored very highly in terms of manufacturability and cost effectiveness. The prototype device, seen in Photo 3, was manufactured with common wood-working tools and assembled from components available at most hardware and electrical supply stores. The ability to easily and cheaply manufacture additional devices with “off-the-shelf” components was very attractive to the customer and also eased the manufacturing responsibilities of the design team. Anyone with an understanding and ability to use a jigsaw and hand drill can duplicate the device in a relatively short amount of time, 4 to 5 hours. In order to assure customer satisfaction in the final device, the team periodically presented their progress to workers and management at the Workshop and used their input to guide the device's further evolution.

|

|---|

RESULTS

The beta prototype for our product was successfully manufactured. It works in the following manner:

- Load the roll of stickers and pull the initial backing paper and stick it to the backing paper roll. (Initial Set-up done by the supervisor)

- Switch the main switch to the ‘on' position.

- The sticker dispenser is ready to roll out stickers. As the first sticker rolls out, it blocks the light to the optical sensor, which stops the motor. After the sticker is pulled out from this position, the motor starts again, and another sticker rolls out. This process continues till the stickers from the roll get exhausted.

The sticker dispenser was successfully demonstrated at the Rolla Area Sheltered Workshop. The supervisor and the worker operating the machine were completely satisfied with our product.

One of the important customer needs for our product was safety of the users, which was very well taken care of. The sticker dispenser is shielded from all sides so that no moving parts or sharp corners are exposed. Another important aspect of the device is its low cost. Similar commercially available sticker dispensers are in the price range of $400-800. Our product costs approximately $140, which makes more affordable to the Workshop and other similar facilities. This product is also very easy to use, and can be operated with either the right or left hand. Thus, the sticker dispenser our team has developed works very well satisfying all the customer requirements.

REFERENCES

- Otto, K. and Wood, K. (2001), Product Design: Techniques in Reverse Engineering, Systematic Design, and New Product Development, New York, Prentice Hall.

- Hirtz, J., Stone, R., McAdams, D., Szykman, S., and Wood, K. (2002), "A Functional Basis for Engineering Design: Reconciling and Evolving Previous Efforts." Research in Engineering Design, 13(2):65-82

Author Contact Information:

David Comella, BS,

914 West 10 th ST, #3,

Rolla, MO 65401,

Home Phone (573)

426-5752

EMAIL: dac4z3@umr.edu