Lawn Care Assisting Device

Eric M. Spitz, Jordan M. Sadowsky, & John M. Schoenleber

Duke University

Durham, NC 27708

ABSTRACT

The Lawn Care Assisting Device (LCAD) has been developed to help our client, a woman who uses a manual wheelchair, to garden independently. The device’s irregular shape maximizes usable space and increases tool accessibility. The LCAD is composed primarily of Lexan® and uses swivel caster wheels for optimal maneuverability. A sturdy removable shelf and a rear flap maximize the device’s functionality. The LCAD easily attaches to and detaches from the wheelchair using a simple mechanism composed of a hook and two aluminum rods. It transports items such as a watering pail, gardening tools, and yard waste, and allows users to rake into and out of the chamber. Our client has successfully used the device to water her garden and transport large piles of leaves among other tasks. The LCAD can easily be adapted for other gardeners with different landscapes and wheelchair models.

KEYWORDS:

gardening; garden cart; outdoor device; transport equipment; wheelchair attachment

BACKGROUND

Our client is an avid gardener with spina bifida, a congenital abnormality leading to irregularities in the spinal cord and vertebral arches due to a failure of fusion in the caudal portion of the neural tube (1). This defect often leads to deformities of the knees, hips, and feet as well as an overall loss of muscle tone (2). Our client uses a manual wheelchair, which makes it difficult for her to perform several gardening tasks. Specifically, she is unable to transport her watering pail, gardening tools, leaves, twigs, and other yard waste.

A number of patented, attachable wheelchair devices have storage capabilities (3, 4). Such devices, however, do not meet our client’s needs because they do not provide enough weight support and contain openings that allow small fragments to fall through. In addition, many provide poor accessibility and contain inadequate space. Therefore, a specialized device is needed to help make gardening more enjoyable and productive for our client and others that use wheelchairs.

PROBLEM STATEMENT

This project’s goal was to create a device that enables our client to transport yard waste (e.g. leaves), a watering pail, and gardening tools around her yard while in her wheelchair. Important objectives included overall safety, device strength, negligible interference to wheelchair maneuverability, durability, and tool accessibility.

DESIGN AND DEVELOPMENT

Our design process centered on four-steps: an initial idea to solve the client’s needs, a spatial prototype, a functional prototype, and a final product. We first met with our client at her home and addressed her difficulties in gardening while using a wheelchair. Our client desired a device that would transport yard waste (such as leaves), carry tools (a rake, clippers, etc.), and carry a full water pail. Several functional specifications such as durability, weight, safety, obtrusiveness, and the effect on the wheelchair’s mobility became the immediate concerns in preliminary design.

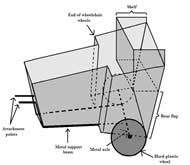

Taking these needs and specifications into consideration, a preliminary design was developed that comprised a rigid frame attached to large wheels, a primary chamber designed to hold yard waste, and an elevated shelf to hold tools and water (Photo 1). The rigid frame ran from the wheels along the base of the cart and connected into safety wheel attachment cylinders. Our client’s wheelchair features two safety wheels that are easily removable and viewed as unnecessary by our client. The primary chamber was designed to contour the wheelchair. Once the wheels were cleared, the chamber widened to the width of the chair in order to maximize storage space in the main chamber. It also featured a rear flap that could be opened to rake yard waste into or out of the chamber. The final part of our initial design was an elevated shelf. This shelf was designed to be within reach of our client while seated in the wheelchair and strong enough to hold all small tools and water in a convenient location above the yard waste.

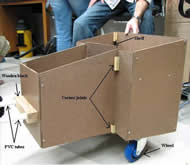

We then met our client to take measurements of the rear of the wheelchair to determine the maximum size of the cart. From these, a spatial prototype (Photo 2) was constructed to test for size. This prototype was constructed out of 11 pieces of tempered hardboard (eight for the walls, one for the base, and two for the shelf). These pieces were attached together using wooden blocks, screws, and nails as stability and aesthetics were not a serious concern. Caster wheels were bolted to the bottom of the cart and the shelf was made removable by resting it on blocks. A front attachment of scrap wood and PVC was created to slide into the safety wheel cylinders. This prototype was then tested in order to verify size and mobility.

Several changes were noted at testing for the second, functional prototype (Photo 3). These changes included shortening the front part of the main chamber by 4”, lowering the shelf 1”, creating a hinged flap on the back (Photo 4), and redesigning the attachment mechanism to fit and lock with the chair. The rear flap was hinged, and when closed, connected to an upper crossbar by Velcro®. A refined attachment mechanism was created with two tubes providing support in the vertical and horizontal direction, and a hinged hook providing support in the pull direction. This prototype was successfully tested.

The final product was then constructed to meet the functional specifications of durability and strength. Lexan® polycarbonate replaced all wooden panels (Photo 5). The primary chamber was built with 0.375” Lexan® walls and a 0.22” polycarbonate base that was attached using stainless steel, screws threaded into the Lexan. Caster wheels were bolted onto the bottom of the cart, and the shelf (made from 3/8” Lexan®) was designed to rest on Lexan® blocks. The front attachment mechanism comprised Lexan® blocks and aluminum rods (Photo 6). The rear flap (a 0.093” sheet of Lexan®) was attached by a piano hinge. A lawnmower pull cord raised the flap, and magnets, inlayed into the crossbar, connected with metallic sheets inlayed into the flap to secure the flap (Photo 7). Ergonomic handles were added to the shelf and the inside of the front panel to facilitate lifting. Attachment hooks for the shelf were added to the side of the cart for use when the shelf is removed, drainage holes were added in the front of the bottom panel, and a circular sander was used to smooth all corners and give the Lexan® a scratch-resistant, foggy look (Photos 8 and 9).

EVALUATION

The main purpose of the LCAD is simple, mass transport of gardening tools and yard waste. After testing the device with our client, the device appears to meet all objectives and exceeds our client’s expectations. The device is easily attachable and detachable from the wheelchair by the user, ensuring independent use. All of our client’s tools fit either in the main chamber or on the shelf. The weight of the LCAD, even when carrying a full watering pail, does not hamper her mobility, as she still can ascend the steepest incline in her garden. Our client can, without difficulty, carry a watering pail, reach behind her chair to grab the pail, and then water her plants – all while sitting in her chair. Likewise, our client has no trouble lowering the flap and raking leaves directly into the main chamber. In addition, she is able to raise the flap and dump yard waste to a large pile. The shelf is easily removable and storage is convenient on the side of the cart. With extended use, our client will become even more proficient with the device’s features and improve her techniques to maximize the LCAD’s functionality.

DISCUSSION AND CONCLUSIONS

Major advantages of the LCAD stem from its specialization of use (i.e. gardening) and its unique structure that was tailored for our client’s particular tools and wheelchair, the TiLite ZRc. These advantages include its simple removability, minimal obtrusiveness, durability, sufficient storage space, suitable strength, and additional features to aid in important gardening tasks (e.g. flap assists in raking, shelf increases the accessibility of hand tools and watering pail). Due to its strong and durable composition, the LCAD costs more than typical storage devices, with a replacement cost of about $310. Another disadvantage is that the attachment mechanism was designed specifically for our client’s wheelchair, and therefore would need to be adjusted to work with other wheelchair models. The LCAD has met all of our objectives, enabling our client to actively and independently perform gardening tasks that she previously could not do.

REFERENCES

- Mitchell, L.E., Adizick, N.S., Melchionee, J., Pasquariello, P.S., Sutton, L.N., & Whitehead, A.S. (2004). “Spina bifida.” Health Source: Nursing, 364 (9448): 1885-1895.

- Northrup, H., & Volcik, K.A. (2000). “Spina bifida and other neural tube defects.” Curr Probl Pediatr, 30 (10): 313-32.

- Shirk, LV. Holder apparatus attachable on a wheelchair. U.S. patent 4,861,059. 1989 Aug.

- Trubiano, A. Container basket for wheelchair. U.S. patent 4,339,063. 1982 Jul.

ACKNOWLEDGMENTS

This material is based upon work supported by the National Science Foundation under Grant No. BES-0610534. We would like to thank our professor, Dr. Laurence Bohs, for giving us many insightful suggestions and for providing guidance throughout the design and construction process.

Author Contact Information:

Eric M Spitz

221 Anderson Street, Apt I

Durham, NC 27705

Jordan M Sadowsky

913 Dacian Avenue

Durham, NC 27701

John M Schoenleber

903 Onslow Street

Durham, NC 27705