The Adjustable Camber Axle Plate (ACAP): Redesign of a Wheelchair Axle Plate for Rapid Changes in Wheel Camber

Jay Kothari, Amit Kaushal, Daniel Ramirez, Samir Shah

New Jersey Institute of Technology, Newark, NJ

ABSTRACT

To change the camber, or tilt of a wheelchair’s rear wheels, current wheelchair models require some disassembly of the wheelchair. Camber adjustment is also limited to 2-3 degree increments. In order to assist researchers who have requested fast camber changes with finer resolution for “Quickie” wheelchairs, the Adjustable Camber Axle Plate (ACAP) was designed to allow the adjustment of the camber of a wheelchair’s rear wheels in 1 degree increments without dismantling the wheelchair. The ACAP replaces the existing axle plate without altering the dimensions of the existing “Quickie” wheelchair. This ensures mobility through standard doors and ramps, while maintaining the structural integrity comparable to that of the original wheelchair. Camber of both wheels can now be changed within 90 seconds from 0 to 10 degrees without tools. Researchers will use this modification to quickly and easily adjust camber angles. This will increase efficiency when conducting research on optimal camber for patients.

KEYWORDS:

Camber, Axle plate, Wheelchair, Quickie GPV

BACKGROUND

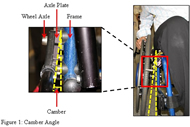

Camber is defined as “the outward or inward tilt of a wheel measured as the angle in degrees between the vertical and the plane through the circumference of the wheel,” as shown in Figure 1 (1). When camber of a wheelchair is increased, the distance between the rear wheels is increased at the floor. Therefore the wheels are closer together at the top making the wheelchair more stable. Properly cambered wheels allow for a more natural movement of the shoulder joint, reducing unnecessary strain. In addition, it also allows for the person to access the pushrim more effectively, allowing longer strokes; thus, more power output per stroke. Often, the best camber is not the same for each patient, and researchers are currently using biomechanical models to understand how camber affects push dynamics and biomechanics. This research will help identify optimal camber to maximize arm stroke efficiency and reduce injury.

Not all wheelchairs are available with cambered wheels, and only some allow for the adjustment of camber. These camber changes are available only in increments of 2-3 degrees, where most of them require removal of the wheels or axles as well as purchasing additional parts to achieve the desired camber.

Researchers have requested modifications to a Quickie GPV wheelchair that would provide the following functionality:

- Allow for camber adjustment without removing wheels

- Support a camber range from 0° to 10°

- Allow camber to be adjusted in 1° increments

- Allow adjustment of camber of each wheel within 2 minutes

- Be adjustable with only simple hand tools

- Maintain existing wheelchair features and safety ratings

METHODS/APPROACH

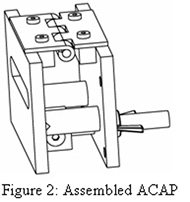

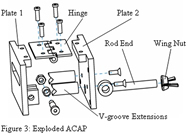

In order to adjust camber quickly and efficiently, it is necessary for the axle plate to have a degree of freedom. Being the original axle plate is just a single, static plate mounted between the frame of the wheelchair and the axle, there are no degrees of freedom to allow for adjustment. The ACAP solves this problem by using a two plate system, with a hinge mounted between the two plates, giving it a rotational degree of freedom.

Plate 1 is mounted in place of the original axle plate, behind the wheelchair frame. Plate 2 is connected via a hinge to Plate 1. The circular rod end passes through Plate 1 and is secured by a wing nut on the opposite side. This allows angular movement of Plate 2. Two cylinders with v-grooves are mounted on Plate 1, facing Plate 2.

The spacers consist of a set of cylindrical rods of varying diameters. Two spacers of equal diameter are placed between Plate 2 and the v-groove extensions. A certain diameter of the spacer corresponds to a respective change in camber. After loosening the wing nut and placing two spacers, the system is tightened to achieve a desired camber.

The wheelchair must be unloaded in order to adjust the camber. To change the camber, reach behind Plate 1 and unscrew the wing nut. It is not necessary to unscrew it completely; just enough to remove the current spacers and place the new spacers. There is a ring magnet located on each v-groove extension; move them as close as possible to the v-grooves. They assist in placing the new spacers because the spacers used are magnetic. Place the pair of spacers in each of the v-grooves. Verify that the two spacers have the same diameter. Once both spacers are in place, grab the bottom edge of both plates and close them. Once closed, ensure that both spacers are inside the v-grooves. Once the spacers are properly inside the v-grooves, and the axle plates are closed, tighten the wing nut. Repeat for the other wheel.

EVALUATION

The average time to change the camber of both wheels while unloaded is approximately 90 seconds. No tools are required in the process.

The plates are made of 7075 aluminum alloy; v-groove extensions are of 7068 aluminum alloy. The materials chosen are also rated to handle loads much higher than what the wheelchair frame itself can support, as to maintain the integrity of the wheelchair. The estimated cost of materials for two ACAPs is $382. If mass produced, this amount can decrease significantly.

CONCLUSION

The ACAP is developed to be used in a research study to determine the optimal camber angle for general use. Due to varying height and arm length, a camber of 0 degrees may not allow for maximum power output per stroke, and may also cause injury to the shoulder joint. The research study will test how varying the camber from 0 to 10 degrees, in 1-degree increments, affects power output and shoulder joint strain.

The ACAP is designed to work with a Quickie GPV wheelchair, although the concept can be extended to other models as well.

REFERENCES

- “Camber.” Dictionary.com. 2006. 12 Oct. 2006 <http://dictionary.reference.com/browse/camber>.

CONTACT INFORMATION

Jay Kothari

102 West Central Avenue

Maywood, NJ 07607

P: 201-951-6990

F: 201-587-7662

E: jk57@njit.edu