Shoe Helper

Andy Huang, John Perkins, Alyx Rosen

Duke University

Durham, NC 27708

ABSTRACT

Our client, a woman with cerebral palsy and limited mobility in her legs, has difficulty putting on her shoes. Her current method may take up to forty minutes. We have developed a device to help our client put on shoes quickly and easily. The Shoe Helper, made from thermoplastic, consists of a shoehorn pivoting on top of a heel sleeve. While the heel sleeve prevents the heel of the shoe from folding under, the extra-wide shoehorn supports our client’s heel and provides a direct angle for inserting the foot into the shoe regardless of the foot’s entry angle. A string attached to the shoehorn allows her to rotate the device. She also uses the top of the shoehorn as a sock aid, minimizing the number of dressing aids needed. The product is portable, adaptable to all shoes, and inexpensive to produce. Using the device, our client now puts on both socks and shoes in under four minutes.

KEYWORDS:

Shoe helper; shoe aid; sock aid; shoe device; shoehorn; heel sleeve

BACKGROUND

Our client is a professional woman who has Cerebral Palsy, a neurological disorder that affects muscle movement and coordination (1). As a result, she has limited mobility in her legs and feet and uses a manual wheelchair. Putting on shoes or socks is a difficult task. Currently, she puts her shoes on by using a reacher to grab the shoe and pull it onto her foot (Figure 1). This usually leaves the heel of the shoe resting below the middle of her foot (Figure 2). She then maneuvers the rest of her foot into the shoe by simultaneously pushing her leg downwards and rolling forward with her wheelchair. Numerous complications can make the process more exhausting and time consuming. The back of the shoe often folds under her heel while pushing her foot into the shoe. She has good arm mobility and strength, but cannot comfortably reach her feet to fix this problem (Figure 3). In addition, she cannot reliably adjust her legs and feet to approach the shoe at a direct angle.

Many devices are available to aid in the application of shoes and socks. Footwear Solutions offers a Long Handled Shoe Horn for those who cannot reach their feet (2). The shoehorn is shaped to match the curvature of the heel but does not support our client’s entire heel. The FootFunnelTM (3) is a plastic funnel that sits around the heel of the shoe. An attached string allows the user to remove the device from the shoe. The problem is that the funnel does not fit our client’s shoes and fails to guide her foot into the shoe. Most commercially available products also require the user to be in a standing position or bend down and reach behind the legs. Since our client cannot perform these actions, the Shoe Helper incorporates some of the features of existing technologies while catering to her specific requirements.

PROBLEM STATEMENT

The goal of this project was to design a device to enable our client to put on her shoes quickly and easily. The final product needed to be lightweight, portable, and aid in putting on different types of shoes.

DESIGN AND DEVELOPMENT

The design process began in the initial meeting with our client where she demonstrated the difficulties associated with putting on her shoes. The first problem occurred when the back of the shoe folded beneath the heel. The second problem involved the difficulty our client faced in using a long-handled shoehorn. The wheelchair prevented her from reaching behind her legs to properly position the shoehorn. Also, our client’s heel would continually slip off the shoehorn because it was too narrow to support her entire heel.

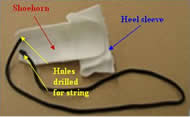

Our initial design incorporated modifications of two existing technologies. First, our client required a shoehorn that was much wider than any commercially available shoehorn. Second, we incorporated a customized heel sleeve that fit on all of her shoes. We constructed both the shoehorn and heel sleeve out of thermoplastic because it easily molds to any shape when heated with hot water or a heat gun, and is very rigid when the thermoplastic returns to room temperature. We connected the two parts by a hinge to permit rotation of the shoehorn into the heel sleeve (Figure 4). The self-adhesive properties of the thermoplastic were useful when attaching the hinge to the shoehorn and heel sleeve: the hinge was sandwiched tightly between two layers of thermoplastic, eliminating the need for screws. Finally, a string was attached to the top of the shoehorn, allowing the user to pull on the string and rotate the shoehorn into the heel sleeve.

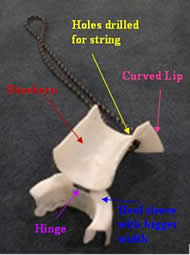

After constructing the prototype, we had our client test the device. The first problem was that the shoehorn and heel sleeve occupied too much space inside the shoe. To fix this problem we repositioned the shoehorn on top of the heel sleeve so that it no longer rotated into the shoe. The second problem involved the fraying and eventual failure of the cotton string. We replaced the cotton string with a more durable hiking shoelace and drilled slightly larger holes. We added a lip to the top of the shoehorn allowing the user to easily grab and remove the device (Figure 5).

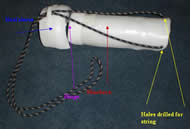

The next problem occurred when we attempted to use the device as a sock aid. The Sock/Stocking Aid (4) is a commercially available device used by our client. She places a sock around the Sock/Stocking Aid, slides her foot into the sock, and then pulls the device up her leg leaving the sock on her foot. To incorporate the sock aid functionality, we removed the curved lip at the top of the shoehorn and also lengthened the shoehorn to achieve a shape similar to the Sock/Stocking Aid. The final modification was the addition of a thermoplastic bracket to the back of the heel sleeve that stabilizes the device when used as a sock aid. The bracket was attached by again utilizing the self-adhesive properties of the thermoplastic. The string is threaded through the bracket before the sock is put over the shoehorn. This allows the user to pull forcefully on the string from the heel sleeve end of the device. These modifications resulted in the final design (Figure 6).

Figure 7 shows the client putting on a slip-on loafer, while Figure 8 shows her applying a stocking.

EVALUATION

Throughout the design process, we met with our client frequently to test out all changes and gain her valuable input. After several initial prototypes we determined that a combination of a custom-sized shoehorn pivoting on top of a heel sleeve was the best solution. Afterwards, more subtle but important modifications were made based on client feedback in order to further fit the design of the device to her needs. The addition of the sock aid functionality was suggested by our client and successfully implemented.

The device has proven to work on all of our client’s shoes including loafers, winter boots, and tennis shoes, as well as socks and stockings. It is also light weight and portable enough to fit in a gym bag. Therefore, the device meets the two most important functional specifications. Our client learned to use the device relatively quickly and it has already reduced her shoe application time from forty minutes to less than two minutes. She is extremely satisfied with the final design and remarked, “This is a life changing tool. It will save me at least three hours each week.”

DISCUSSION AND CONCLUSIONS

The major advantages of the device are its portability, adaptability to different shoes, ease of use, and low cost of production. Total replacement cost for one Shoe Helper is about $18.00. One disadvantage is that this device may require the use of auxiliary items, such as a reacher or wheelchair. However, we anticipate that many potential users of this device will already be using these tools. Future work will involve developing a method of easily manufacturing this device; as of now, all parts are fitted by hand. This device could be marketed to individuals who do not have the flexibility or mobility necessary to use existing shoe aid devices. Possible customers include people with disabilities, the elderly, pregnant women, and those who have sustained back injuries.

REFERENCES

- National Institute of Neurological Disorders and Stroke (NINDS) Cerebral Palsy Information Page, 2001 Jan, http://www.ninds.nih.gov/health_and_medical/disorders/cerebral_palsy.htm.

- "Long Handled Shoe Horn, Shoe and Disability Aids." Footwear Solutions. 17 Sep 2007 <http://www.footwearsolutions.co.uk/proddetail.php?prod=aidsshoehorn>.

- "Heel sleeve." Insightful Products. 17 Sep 2007 <http://www.footfunnel.com/>.

- "AliMed® Sock/Stocking Aid." AliMed: Medical and Ergonomic Products for Healthcare, Business, and Home. 3 Dec 2007 <http://www.alimed.com >.

ACKNOWLEDGMENTS

This material is based upon work supported by the National Science Foundation under Grant No. BES 06-10534.

Author Contact Information:

Andy Huang

P.O. Box 94979

Durham, NC 27708

John Perkins

P.O. Box 94778

Durham, NC 27708

Alyx Rosen

P.O. Box 94431

Durham, NC 27708