Toothbrush Buddy: A Toothpaste Dispenser For People With Motor, Cognitive, And/Or Visual Impairments

Madeline Lee, Meghan Mulloy, Madelyn Betz, Amy Heerten

University of Pittsburgh

1) Problem Statement and Background

Activities of daily living (ADLs) are fundamental skills for self-care, and include tasks such as eating, bathing, toileting, grooming, dressing, and mobility (Katz, 1983). People perform these activities in many ways and may be influenced by individual functional status and dependence on other people or adaptive devices (Edemekong et al., 2021). Musculoskeletal, neurological, circulatory, sensory, and cognitive limitations can impair an individual's ability to independently complete these tasks (Edemekong et al., 2021). Performing ADLs is an integral part of the human experience and can be supported with the implementation of technology to better meet people's diverse needs.

As part of an assistive technology design course in the Masters of Rehabilitation Technology program at the University of Pittsburgh, the design team conducted a case study of Matt, a 19-year-old with autism and a visual impairment, and his family members who are his primary caretakers. The goal of this case study is to identify, design, and implement an assistive technology intervention to enhance functional independence when performing ADLs. The primary ADL Matt's family identified for technology intervention is daily dental hygiene. Due to the subject's limitations in visual field, fine motor control, and task sequencing, the process of locating the toothbrush and toothpaste, applying the toothpaste to the toothbrush, and cleaning up often causes fatigue and frustration. This toothbrushing task was identified as an area of opportunity to better support the subject's independence, thereby building confidence and functional skills. This inspired the design and development of an adaptive toothpaste dispensing device.

This design project was based on a single subject, however the opportunity for this technology to be used for a wide range of individuals with various functional capabilities was soon realized. People with dexterity, cognitive, and/or visual impairments may have difficulty applying the appropriate amount of toothpaste to a toothbrush due to challenges with squeezing the toothpaste container and simultaneously controlling the toothpaste and toothbrush. These challenges impact a person's ability to independently perform necessary hygiene self-care tasks, a fundamental factor in healthy living.

2) Approach and Solutions Considered

This project was completed over two semesters and consisted of remote collaboration between the design team and project stakeholders. The team performed multiple remote observations through pre-recorded videos and live Zoom observations of Matt's tooth brushing routine to identify his specific needs. A task analysis for each step of his tooth brushing routine was performed to categorize areas of difficulty and potential solutions to incorporate into the device design. The most challenging task for the subject is the application of toothpaste onto the bristles of the toothbrush. His visual field is limited (i.e., difficult to see if the toothpaste is on the toothbrush bristles) and the motion of holding the toothbrush steady and squeezing out an appropriate amount of toothpaste onto a relatively small target is difficult.

The team conducted nine additional interviews with various stakeholders, including a fourteen-year-old boy with autism, his mother, two adults with visual impairments, and five instructors who teach various functional skills to individuals with visual and other impairments. This process identified the primary needs for the toothpaste dispensing design as it relates to a diverse population with various functional needs. Seven User Needs for Toothbrush Buddy's device were identified and are listed as follows. First, the user can apply the toothpaste on the toothbrush independently, within functional limits. Second, the user can align the toothbrush to the toothpaste dispenser with minimal fine motor control. Third, the device dispenses the right amount of toothpaste consistently. Fourth, the device dispenses the toothpaste with minimal spillage and mess. Fifth, the device provides feedback indicating the toothpaste is on the toothbrush. Sixth, the device has high contrast elements. And seventh, the device is non-toxic and made of food-grade safe materials. Each of these features were incorporated into the Toothbrush Buddy design for testing.

There are various products on the market that aid with dispensing toothpaste. Examples include generic toothpaste dispensers, tube squeezers, and toothbrushes that contain toothpaste internally. Preliminary analysis indicated these products do not meet all identified user needs. The product that most closely aligns with the design team's vision of affordability, accessibility, and ease of use is the Amazon iHave Toothpaste Dispenser Wall Mount. After trialing this device, we discovered that it did not follow universal design principles. We found issues with the opening for the toothbrush, lever mechanics, and lack of feedback. It was difficult for Matt to line up the toothbrush with the opening of the device and be in the proper location on the lever. These problems would cause the toothpaste to inconsistently land on the toothbrush, resulting in messes. In addition, the iHave did not have high contrast elements making it difficult for people with low vision to find the opening. The iHave dispensed inconsistent amounts of toothpaste and dispensed too much toothpaste. Research shows that for children and adults who can brush their teeth independently, only a "pea size" amount of toothpaste is necessary (American Academy of Pediatric Dentistry, 2011). The iHave also did not provide audio or tactile feedback to the user to indicate that toothpaste is on their toothbrush.

To create a more universal design, modifications to the iHave device were first done with household materials such as cardboard, sponges, and tape to simulate a device that better addressed user needs. This was the first looks-like prototype and built the foundation of the track and lever designs for this product.

Following secondary consultation with project stakeholders, track and lever toothpaste dispenser attachments were created using Computer-Aided Design (CAD) software and printed using FormLabs Resin. Matt tried the first functional prototype. Matt's mother answered a Likert-scale questionnaire on a scale of one to five that addressed the subject's level of independence, perceived effort, goal attainment, and the device's ability to accurately dispense toothpaste with minimal mess. Additional qualitative data was gathered related to the subject's overall reaction to the device, how it compares to his current routine, features of the device that are working well, and features that need improvement. After this initial trial, each component of the design was iterated further to meet user needs and was driven by user feedback, validation, and verification.

To meet the second user need of aligning the toothbrush to the dispenser, a track attachment was designed. The team initially considered two different track design options: a newly designed front cover with a V-shape track attached or a track that can attach to the existing iHave front cover with press fit connections. For simplifying the design for manufacturing and color contrast, we decided to use the iHave front cover and design a track attachment. The team iterated the track shape and ultimately decided on a box shape track attachment for maximal stability, control, and alignment of the toothbrush.

Next, the team considered solutions to meet the third user need of dispensing the correct amount of toothpaste consistently. The team initially considered using mini-cell foam on the back of the dispenser to prevent the lever from pushing too far back to release the proper amount of toothpaste. At the same time, the team was finding ways to address the fifth user need of providing feedback to the user that toothpaste is on the toothbrush. The team considered several noise making devices to mount on the back of the dispenser including fidget cubes, dog squeakers, and dog clickers. After testing such noise makers, the dog clicker was chosen to provide the user with tactile and audio feedback. Three different brands of dog clickers were tested and compared to one another to find the ideal sound and feeling. The team realized that the dog clicker feedback mechanism could prevent the lever from pushing too far back in the same way that the mini-cell foam could, meeting the third user need.

The fourth user need of dispensing toothpaste with minimal spillage was met by replacing the existing iHave lever with our lever design. The team considered having the lever funnel the toothbrush to a desired location but found it unnecessary as the track already aligned the toothbrush. The shape and design of the lever was iterated to improve functionality. The team tested different plastics with various elastic properties to decide which would be most ideal given its desired function.

The solution of combining the lever and track together as one piece was considered. This idea was abandoned after multiple tests and iterations proved that the toothpaste inconsistently landed on the toothbrush. Through the design and iteration process, the design was finalized to increase the user's independence in brushing their teeth.

3) Description of Final Approach and Design

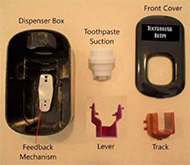

Toothbrush Buddy's finalized components consist of a track attachment, replacement lever, and an audio and tactile feedback mechanism. The iHave device with our added features is secured to the wall with Removable Interlocking Fastener Command Strips.

The track attachment locks into the back face of the Front Cover of the iHave dispenser. Five clips on the track attachment latch onto the iHave cover, locking it in place. The track protrudes out of the dispenser box making it easy to find the opening without the aid of vision. When using Toothbrush Buddy's product, the user inserts their toothbrush into the track with the bristles facing upwards. By keeping the bottom of the toothbrush along the flat bottom surface of the track, the toothbrush stays in the correct orientation keeping the bristles facing up. As the user pushes their toothbrush deeper into the dispenser, the track keeps the toothbrush straight in the forward direction guiding the toothbrush to the right location to activate the dispenser correctly. Improving the alignment of the toothbrush into the dispenser satisfies User Need 2. By aligning the toothbrush in the correct orientation and location, the track reduces spillage and mess of the toothbrushing process, satisfying User Need 4.

The dispenser is a black box, and the track is red. The tested user of the device responds well to these colors in contrast with one another, meeting User Need 6 of the device being high contrast. This allows the user to find the opening more easily. Note that the color of the track attachment and box depends on the user's abilities and needs. Possible colors for these parts are red, orange, yellow, green, blue, purple, white, or black.

The second component to the Toothbrush Buddy system is the lever. The new lever has a narrow opening to control the toothbrush location and positions the toothbrush closer to the nozzle of the toothpaste dispenser. Now, the toothpaste lands on the toothbrush bristles more precisely and accurately than the iHave design. This satisfies User Need 4 as it minimizes spillage and mess.

An audio and tactile feedback mechanism is mounted on the back wall of the dispenser. This mechanism is made from metal from a dog clicker and is mounted through hot glue and a spacer made of plastic. When the lever depresses to the point that the right amount of toothpaste is released, the lever flexes the metal, and a click noise is heard. The user can also feel a slight vibration in their hand when the feedback mechanism is activated. When the user withdraws their toothbrush, a second click is heard as the metal returns to the neutral, unflexed position. This mechanism meets User Need 5 by providing feedback to the user when the right amount of toothpaste is on the toothbrush and when to remove the toothbrush. This mechanism has a second purpose of limiting how far the lever can depress, so that the correct amount of toothpaste is released every time, meeting User Need 3.

To meet Need 7, all the materials of the device are non-toxic, which include the iHave dispenser, 3D printed components, metal, and spacer. By satisfying Needs 2-6, this device increases the user's independence for brushing their teeth given the target customer which, in turn, satisfies User Need 1. Future iterations of the design to improve the consistency of the amount of toothpaste dispensed, decrease small messes that occur, and increase the stability of the track onto the front cover are necessary.

4) Outcomes

Verification and Validation testing of the device were used throughout the design process to determine if the device meets established user needs. The results described in this section are based on the final design product. Verification tests included testing: the security of the device on the wall, mass of toothpaste dispensed, spilled, and accurately landing on the toothbrush from the device, presence of audible feedback, high contrast, and presence of toxic materials.

By using the device 100 times over the course of two months, the Heavy-Duty Command Strips kept the dispenser sufficiently secure on the wall. On average, 0.40 g of toothpaste is dispensed from the Toothbrush Buddy device, 0.38 g of which land on the toothbrush, leaving about 0.01+ g of spillage per use. These results all fall within our desired expected range of values satisfying Need 3 and 4 (American Academy of Pediatric Dentistry..., 2011). Using a decibel meter, tests showed that the audio feedback averaged about 76.1 dB which is within the 0-85 dB safe range of average human hearing, supporting Need 5 (Lutman, 2000). The red track element contrasts with the black front cover of the device in a ratio of 5.49:1 which is above the threshold of 4.5:1 required for image web accessibility, satisfying Need 6 (US Access Board, 2016). The contrast ratio was calculated using an online contrast checker. Lastly, the team researched the material properties and toxicity of every component added to the Toothbrush Buddy device and concluded that no elements are toxic, satisfying Need 7.

Validation tests included time to complete the task, usability, mass of toothpaste on the toothbrush, spillage occurrence, user knowledge of toothpaste on the toothbrush, tactile and audio feedback awareness, and high contrast awareness while the user is operating the device. The time on average it takes Matt to follow his normal routine from finding the toothpaste and toothbrush, wetting the toothbrush, uncapping the toothpaste, and applying toothpaste is 63.3 seconds. The time on average it takes Matt to use the Toothbrush Buddy to accomplish the same task is 42.7 seconds. By using the Toothbrush Buddy, Matt is more independent and can do the task more efficiently.

The System Usability Scale (SUS) was used to gauge the usability of the Toothbrush Buddy for users. A score of 68 or above indicates that the device is above average. Matt and his mom answered the SUS questionnaire and gave the device a score of 70. When Matt used the dispenser, the mass of toothpaste on the toothbrush averaged 0.255 g. This indicates that the device released the correct amount of toothpaste each time, between 0.25-0.5 g, meeting user need 3. The difference between this validation test and the mass of toothpaste dispensed verification test above could be due to a difference in toothpaste, minute differences in tested prototypes, etc. During observation of Matt using the Toothbrush Buddy dispenser, the device had little to no spillage, meeting user need 4. Matt was able to distinguish when toothpaste was on his toothbrush due to the tactile and audio feedback. He was able to indicate that he could hear and feel the feedback, meeting user need 5. Matt could also distinguish the red track from the black dispenser box, meeting user need 6.

5) Cost

| Item | Unit Cost | Quantity | Total Cost |

| Black iHave | $6.99 | 1 | $6.99 |

| Dog clicker - Good2Go | $4.99 | 1 | $4.99 |

| Nylon Spacer | $1.52 | 1 | $1.52 |

| Hot Glue | $8.36 | 0.005 | $0.04 |

| Lever - FormLabs Tough, cost per gram | $0.16 | 5.58 | $0.90 |

| Track - FormLabs Tough, cost per gram | $0.16 | 13.23 | $2.14 |

| Command Strips | $10.99 | 0.125 | $1.37 |

| Production Cost: | $17.96 | ||

| Expected Price: | $26.95 |

It costs a total of $17.96 to create our prototype. With a 50% mark up, the expected price of our product is $26.95. One black iHave device costs $6.99, the Good2Go clicker costs $4.99, the nylon spacer placed behind the clicker is $1.52. The amount of hot glue used costs $0.04. The amount of plastic used for the 3D printed lever and track costs $0.90 and $2.14, respectively. Lastly, the amount of command strips used cost $1.37.

6) Significance

The goal of this toothpaste dispensing device is to support individuals to achieve their personal level of functional independence in completing daily self-care tasks. This technology can apply to a diverse consumer group beyond those with physical, cognitive, or behavioral impairments, including young children learning self-care tasks or older individuals with hand weakness and related challenges with aging. The design team aimed to make this device low-cost so that more people could access the technology or be able to replicate the device with common household products. The implementation of inclusive designs, in addition to being affordable, allows individuals greater opportunities to access assistive technologies to support and improve quality of life.

References

American Academy of Pediatric Dentistry reference manual 2011-2012. (2011). Pediatric dentistry, 33(6 Reference Manual), 1–349.

Edemekong, P. F., Bomgaars, D. L., Sukumaran, S., & Levy, S. B. (2022). Activities of Daily Living. In StatPearls. StatPearls Publishing.

Katz, S. (1983). Assessing self-maintenance: Activities of daily living, mobility, and instrumental activities of Daily Living. Journal of the American Geriatrics Society, 31(12), 721–727. https://doi.org/10.1111/j.1532-5415.1983.tb03391.x

Lutman M. E. (2000). What is the risk of noise-induced hearing loss at 80, 85, 90 dB(A) and above?. Occupational medicine (Oxford, England), 50(4), 274–275. https://doi.org/10.1093/occmed/50.4.274

US Access Board. (2016) Contrast Accessibility Requirements. ICT Baseline Access Board. https://ictbaseline.access-board.gov/08Contrast/

7) Acknowledgements and References

The Toothbrush Buddy team would like to greatly acknowledge UPitt's design academic staff for guidance on this project, without whom none of this would have been possible. Thank you: Mary Goldberg, Jonathan Pearlman, and Alexandra Delazio. They provided great resources, had amazing suggestions and feedback, and continuously kept the team thinking outside of the box. Thank you to all the potential customers that are blind, have autism, and/or gross motor difficulties that took the time to speak with us: Mark Schmeler, Gabe McMorland, Matthew Mulloy, and Jadyn Kaplan. Thank you, Jadyn's mother, Cindy Kaplan, for your help and input to this product. A big acknowledgment to Mathew's mother, Nancy Mulloy, who helped train Mathew in using the Toothbrush Buddy. We'd like to thank Blind Industries and Services of Maryland for the amazing work that they do and for speaking with us: Anica Zlotescu, LJ Bowens, Robert Morgan, and Amy Crouse. Thank you, Tessa McCarthy from the Visual Impairment and Blindness Program at the University of Pittsburgh. Thank you, George Coulston for speaking with the team about IP and bringing this product to market. The biggest thank you again to Matthew Mulloy, the inspiration and main user of this product.