Project A.R.M.: Advancing Above-Elbow Prosthetics with Open-Sourced, Low-Cost Designs for Global Rehabilitation Needs

Emese Elkind¹, Aung T. Tun², Cole McCauley¹, Noah Learned¹, Max Wolkoff¹, Amina Najib¹, Kyla Wisener¹, Lauren Windover¹, Alina Gammage¹, Gabor Fichtinger¹, and Kanchana Thornton²

¹Queen's University, Kingston, Canada

²Burma Children Medical Fund (BCMF), Mae Sot, Tak, Thailand

PROBLEM STATEMENT

THE Burmese healthcare system faces significant inadequacies, worsened by the 2021 military coup in Myanmar. Thousands of refugees seek medical aid in Thailand, yet many, struggle to access healthcare due to their lack of immigration status. The Burma Children Medical Fund (BCMF)¹ in Mae Sot, Tak, Thailand, has provided medical assistance to Burmese patients since 2006. Since 2019, BCMF has operated a prosthetics and orthosis program offering low-cost, 3D printed, body-powered prosthetics. BCMF's resources include seven 3D printers and a staff of five with limited Computer-Aided Design (CAD) experience. Queen's Biomedical Innovation Team (QBiT)² seeks to address this challenge by modifying open-source 3D prosthetic designs to better serve patient needs, particularly by introducing an above-elbow prosthetic to complement the existing below-elbow models. This collaboration will enhance BCMF's capacity to deliver affordable, functional prosthetics to an increasing number of patients affected by the civil war. Myanmar is now the world's deadliest country for landmine and unexploded ordnance casualties, with more than 1,000 victims in 2023 alone, surpassing all other nations. The growing number of amputees in refugee camps due to landmine injuries and lack of medical care highlights the urgency of this project. Current prosthetic solutions for above-elbow amputations vary significantly in design, functionality, and affordability. Traditional myoelectric prostheses offer high degrees of motion and grip precision but are expensive, require complex maintenance, and depend on electricity. For patients in low-resource settings and in harsh climates, these devices are often impractical and unattainable. Body-powered prostheses, such as those using a harness and mechanical linkages, offer a more viable solution due to their affordability, ease of repair, and functional adaptability. Previous research has highlighted the potential of 3D printing in prosthetic development, with successful applications in creating customized, cost-effective limb replacements. The Kwawu Arm 2.0 model found open-sourced, for instance, has demonstrated practical use in developing countries. However, these designs predominantly focus on below-elbow prosthetics, leaving a gap in accessible above-elbow solutions. By adapting existing models and designing new components tailored to refugee healthcare contexts, QBIT aims to bridge this gap and create a 3D printed, low-cost above-elbow prosthetic known as the Assistive Reach Mechanism (A.R.M.).

METHODS

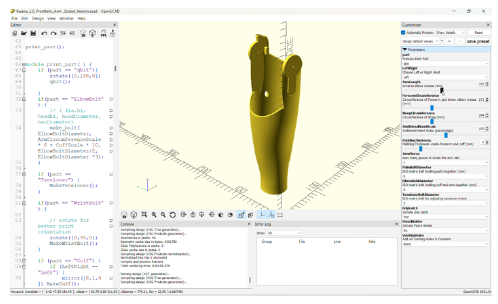

BCMF currently provides custom fitted, low-cost, 3D printed prostheses that are found on Thingiverse³, a public library of 3D designs. One such design is the Kwawu Arm 2.0, which can be adjusted with OpenSCAD⁴, a software for modifying 3D CAD models to fit the recipient's measurements. To maintain BCMF's workflow, the shoulder was created using the 3D design software, Autodesk Fusion 360⁵, by referencing a human shoulder image imported into the software and building a CAD structure around it, closely replicating a human-like shoulder. The shoulder was sized to fit the available forearm from the Kwawu Arm. A screenshot of the developed CAD model is as seen in Figure 1.

The A.R.M. is assembled by first printing the necessary components, including the gripper hand and thumb, wrist bolt, Kwawu 2.0 modified forearm, and shoulder component. Next, the harness is prepared by cutting three black straps and fixing them to an anchor ring and to the prosthetic shoulder socket. The harness is adjusted to the patient's back for a secure and comfortable fit as seen in Figure 2. Once the harness is ready, the shoulder socket can be attached to the rest of the prosthetic components. A hole is drilled into the forearm to attach the elbow joint, ensuring proper alignment based on patient measurements. The wire that opens the gripper hand is then internally routed from the hand to the anchor ring.

The prosthetic consists of four 3D printed components: the hand, wrist bolt, forearm, and upper arm which are 3D printed, assembled with zip ties, elastics, metal springs, and screws, and tested for durability and comfort both with and without patients. An adjustable harness made from materials found at BCMF secures the prosthetic to the patient. An OpenSCAD file was made to enable customization of the prosthetic by BCMF for each patient as seen in Figure 3. The design is optimized for BCMF's available 3D printing technology and workflow, ensuring compatibility with their current processes and resource constraints. A crucial phase of the project involves iterative patient fittings at BCMF, where users provide feedback on comfort, functionality, and ease of use. This input directly informs design refinements, ensuring that each prosthetic meets the diverse needs of recipients while prioritizing usability and long-term wearability.

FINAL DESIGN

The prosthetic consists of the gripper hand, wrist bolt, forearm, and upper arm which are 3D printed, assembled with zip ties, elastics, metal springs, and screws. The elbow and gripping mechanism of the prosthesis are controlled via shoulder movements, allowing independent operation of both functions. The elbow joint has a wide (~100°) range of motion and is designed to lock in place through the control wire system operated by the patient's shoulder movement. The terminal device, currently a two-part hand with mechanically actuated gripping thumb, is interchangeable with specialized attachments. These include a carrying hook, or bike-adapted mechanism and an attachment that enable five finger movement. While grip strength is determined by an extension spring, the terminal device allows for variable grip closure and locking positions to accommodate different objects and tasks. The 3D printed components of the A.R.M. are manufactured using fused deposition modeling 3D printing. Polylactic acid filament is used for its affordability, accessibility, biodegradability, ease of printing and due to its durability in the harsh climates. Off-the-shelf components including control wires, fasteners, and padding all found in the BCMF workshop are integrated into the design and have been selected with ease of acquisition. A key feature of the A.R.M. is its parametric adjustability, which enables custom sizing for individual patients. BCMF staff collect patient measurements and input them into OpenSCAD, a parametric design software, allowing the model's dimensions to be easily adjusted before printing and fitting.

The internal padding of the socket is added for comfort and the thick webbing and padding of the harness system ensure stability while minimizing pressure points. The A.R.M. assembly is designed for local fabrication and maintenance, with BCMF technicians trained to produce, fit, and service the prosthesis. A sizing and assembly manual is provided to BCMF staff to standardize the production and implementation of the prosthesis. While modular, the device currently requires tools for adjustment and part replacement, this ensures secure connections and seamless fit at key locations. By eliminating electronic components, the design is suited for harsh environments and resource-limited settings, reducing complexity and cost. Interchangeable end-effectors enhance usability for daily activities, while internally routed control wires minimize snagging risks. The final product aims to restore partial range of motion, providing increased autonomy to users.

The A.R.M. has undergone and will undergo iterative design improvements based on BCMF, patient, and other stakeholder feedback. The prosthetic and harness were fitted to and tested on a patient at BCMF to evaluate comfort and mobility. Future development will refine the elbow locking mechanism, explore alternative materials, and optimize the prosthesis' support system to improve comfort over extended periods.

OUTCOME

Preliminary testing has been done both by QBiT and BCMF. Although adjustments are still being made for more seamless movement capability, the prosthetic has been proven to be successful in being controlled by the desired movements and has been deemed comfortable and easy to use. QBiT's testing has been focused on ensuring components of the prosthetic functions properly. While QBiT is not in contact with anyone who fits the criteria to need the device, team members have tested the various movement mechanisms included in the arm. To test the ability of shoulder shrugging to bend the elbow, the harness was secured to a QBIT team member and attached to their forearm. In lifting their shoulders, they confirmed the upward pull on their forearm. While this movement was not sufficient to fully bend their elbow, the upward force was deemed strong enough to pull upward if the forearm weight was instead that of the 3D printed component. To test the ability of the shoulder forward movement to close the hand gripper, the harness was again secured to a QBiT team member, and the 3D printed hand was held. This proved the successful grasping and releasing by the wire mechanism used in the final design. Figure 4 demonstrate the gripping and releasing mechanism being used to successfully pick up an object.

BCMF conducted testing with individuals who met the intended user criteria, providing valuable insights into real-world functionality and user experience. Participants reported that the harness system was generally comfortable but noted that minor adjustments could improve fit and ease of movement. The shoulder-driven control system allowed users to perform essential grasping and releasing tasks effectively, though further refinement is needed to optimize the force required for prolonged use. Additionally, BCMF observed that different body types and levels of upper body strength affected the ease of operation, highlighting the need for an adaptable harness system. Moving forward, QBiT aims to refine the prosthetics design through continuous feedback from patients and practitioners. Improvements will focus on enhancing movement efficiency, reducing strain on the user, and ensuring the device remains comfortable and intuitive for extended wear. Future iterations will incorporate user feedback from BCMF testing to further improve prosthetic performance.

COST

The project budget includes material costs for 3D printing filaments, harness components, and fasteners. Additional funds are allocated for iterative prototyping and testing. The A.R.M. is designed to be an accessible, low-cost solution for above-elbow amputees in low-resource settings. As the device is provided directly to BCMF at no cost to patients, there is no traditional commercial market. Instead, BCMF incurs all manufacturing costs, covering materials, fabrication, and fitting expenses. The project prioritizes cost-effective production, ensuring that all components can be sourced and replaced locally with a minimal financial burden. The primary cost drivers include:

- 3D printing Polylactic Acid filament material for socket, forearm, elbow, and terminal devices.

- Off-the-shelf components, such as control wires, fasteners, and padding.

- Harness materials, including webbing, buckles, and padding.

- Post-processing tools and consumables for assembly and fit adjustments.

Efforts to reduce fabrication costs focus on minimizing print time, optimizing material usage, and standardizing component selection. Future iterations may explore alternative materials or improved manufacturing techniques to further reduce costs while enhancing durability. A breakdown of estimated material costs per prosthesis is outlined in Table 1. This cost structure allows BCMF to scale production while maintaining affordability and accessibility for patients who otherwise would not have access to prosthetic care.

| Component | Cost (USD) |

|---|---|

| 3D Printed Components | $22 |

| Harness Components | $5 |

| Control System Components | $3 |

| TOTAL | $30 |

SIGNIFICANCE

This project directly addresses the critical healthcare barriers faced by refugees and individuals in conflict-affected regions, particularly those impacted by the ongoing civil war in Myanmar. The lack of access to affordable prosthetic solutions disproportionately affects those who have sustained limb loss due to landmines, accidents, and inadequate medical care. By developing an accessible, low-cost, and easy-to-manufacture above-elbow prosthetic, Project A.R.M. provides a vital solution for those who would otherwise have limited or no access to prosthetic care. This initiative empowers the BCMF to expand its prosthetics program, improving the quality of life for individuals in need and fostering long-term rehabilitation opportunities. The humanitarian significance of this project is profound. Myanmar has become the deadliest country in the world for landmine casualties. Many of these individuals seek medical aid in Thailand but face significant obstacles due to their immigration status and the limitations of the existing healthcare infrastructure. BCMF has been instrumental in addressing these challenges by providing medical treatment, including prosthetic care, to refugees and displaced individuals. However, their resources remain constrained, with only a small team and limited 3D printing capacity. By developing a prosthetic specifically designed for the above-elbow amputee population, this project fills a crucial gap in BCMF's capabilities, ensuring that more patients receive effective, durable, and affordable prosthetic solutions. Beyond its immediate impact, the aim for the eventual open-source nature of this design promotes accessibility and global scalability. Other humanitarian organizations and medical institutions can replicate, modify, and improve upon this model, extending the reach of affordable prosthetic care in lower income countries. The project not only enhances the functionality of 3D printed prosthetics but also demonstrates the potential of biomedical innovation in addressing pressing global health challenges. By leveraging technology, collaboration, and a patient-centered approach, Project A.R.M. sets a precedent for future advancements in prosthetic care for under served communities.

Acknowledgments

We acknowledge our collaboration between Burma Children Medical Fund, Queen's Biomedical Innovation Team, the Laboratory for Percutaneous Surgery at Queen's University and our academic mentors. Special thanks to patients and BCMF staff who have provided valuable insight into prosthetic design and implementation.

References

- United Nations, "Children and amputees bear brunt of Myanmar's deadly landmine epidemic UN News," *Global perspective Human stories*. Accessed: Feb. 12, 2025. [Online]. Available: https://news.un.org/en/story/2024/11/1157391

- Arm Dynamics, "Introduction to Myoelectric Prostheses." Accessed: Feb. 12, 2025. [Online]. Available: https://www.armdynamics.com/upper-limb-library/introduction-to-myoelectric-prostheses

- J. Buchanan, "Kwawu Arm 2.0 Prosthetic Socket Version by Jacquin Buchanan Thingiverse." Accessed: Feb. 12, 2025. [Online]. Available: https://www.thingiverse.com/thing: 2841281#google_vignette