Rod Squad Design Brief

Ricky Alonzo, Isaac Niklaus, Taychapat Makkong, Olivia Rossi

University of Pittsburgh

Background

Assistive technology enables independence as well as increasing ability. People with disabilities often need assistive technology in order to accomplish their activities of daily living.1 These tasks look differently for each person depending on the lifestyle they wish to pursue; self-care, feeding, and recreation are the three main branches of ADLs. Recreation is the main focus of this proposal as it allows for the person to grow in terms of their physical abilities in addition to their cognitive and emotional needs.2 Fishing is the activity of choice for this proposal as it allows for a relaxing environment, cognitive focus as well as physical activity.

The "Gone Fishin'" program at UPMC Mercy Rehabilitation Center takes patients from the in-patient recovery wing on a daytrip to go fishing at PNC Park in Pittsburgh. This recreational program aims to get patients accustomed to their new injury and comfortable re-entering the community. This program was started by Char Subrick, PT, and is run by her and a team of volunteers every Wednesday from May to September. This activity offers advancement in both the physical and mental aspects of a new injury. Fishing calls for hand-eye coordination, balance, and upper arm motor skills (both gross and fine). Cognitive skills such as focusing for long periods of time on a line also helps patients. Additionally, on the way to the activity patients are getting real world experience learning how to navigate wheelchair movement on city sidewalks, street crossings, opening doors and various other challenges that come with public transportation. This program offers so many opportunities to show newly injured or disabled people they can be independent.

Problem Statement

Fishing can be a leisurely activity, but it can be challenging for an individual with a disability. Currently there are adaptive fishing poles that can help an individual with a disability reel in a fish, see Appendix A, however participants have stated that they would like to have the ability to cast the fishing line out independently. We aim to construct a reliable and affordable adaptive fishing rod that can aid patients from UPMC Mercy Inpatient Rehabilitation Hospital with limited upper body mobility to independently cast fishing line off of the fishing piers at PNC park. Casting independently empowers patients and improves morale and self-confidence.

Research Question

Can casting independently empower patients and improve their morale and self-confidence? Our aim is to construct a reliable and affordable adaptive fishing rod that can aid patients from UPMC Mercy Inpatient Rehabilitation Hospital with limited upper body mobility to independently cast fishing line off of the fishing piers at PNC park.

Methods/Approach/Solutions Considered:

Virtual Approach to Design

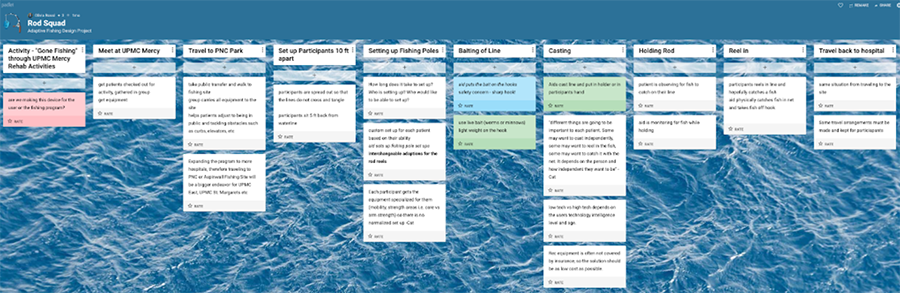

We didn't have a chance to do any physical observations due to COVID-19 but watched a video of the UPMC Gone Fishing Program through a UPMC featurette3. We observed the current products being used in the program and constructed an experience map based on the user experience. This helped us identify pain points and underlying limitations. Our experience map can be seen in Appendix B. We then developed the needs from this map and from various stakeholder interviews.

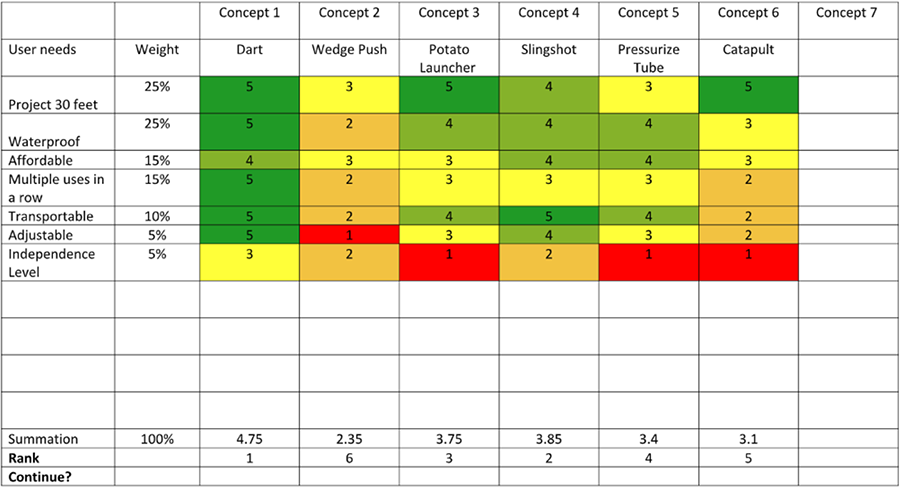

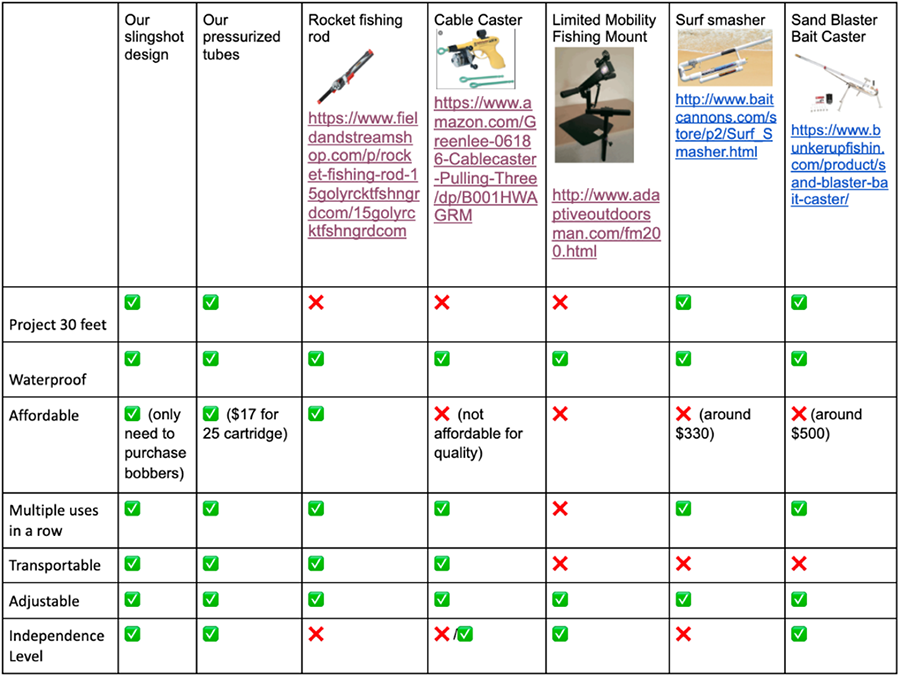

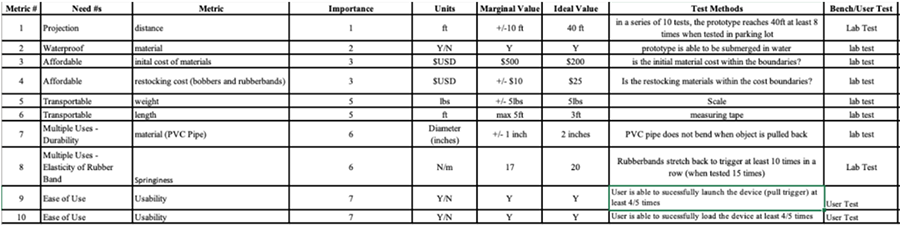

After these interviews, the Rod Squad generated multiple concepts for fishing launchers and had monthly meetings with Charlene Subrick to obtain feedback. These concepts included a pressurized air cannon, crossbow, and a slingshot. The final concept was selected from the top 5 concepts based on a concept matrix (as seen in Appendix C) and feedback from Char and our primary user, Kim Heim. Following this, a benchmark matrix and specification chart were used to compare and develop testing strategies; these can be seen in Appendix D and E respectively.

Construction of prototype

From the feedback we were given from our instructors and from possible end users we decided on constructing the slingshot concept as our first prototype. We first made a list of supplies that were needed in order to construct the design. Once we had our supplies, we then discussed how we were to construct the prototype. We brainstormed ideas of construction with the materials that we had ordered. Once we had our idea, we were able to start constructing the prototype. Fabrication of the prototype consisted of multiple visits to the machine shop in Bakery Square at the University of Pittsburgh. A circular saw was used to cut the PVC pipe to the size we wanted. The CNC router was used to drill the PVC pipe and also construct the custom cut mushroom trigger. We drilled a hole at the end of the PVC pipe to hold the anchor for the slingshot. A lathe machine was used to shave the solid cylinder PCV to the correct diameter for the sled. PVC cement was used to help hold the PVC pipes and elbows together. We than used different resistant elastic bands as the force that would help our design launch. Fishing rod clips helped hold the attachment to the end of the fishing rod.

Testing of prototype

During construction of our prototype, we did some community outreach by posting flyers on social media to local adaptive activity programs in the Pittsburgh area. We got connected with 7 people that wanted to volunteer to test our design. We were able to meet with most of our volunteers to test our product. We asked the volunteers to give us feedback on their experience of the product from beginning to end. This is further explained in the outcome section.

User feedback from solution

At the end of our sessions, we connected with our volunteers via email and asked them if they could fill out a System Usability Scale survey based on their experience of the product. We then scored their responses and based on their scores and feedback we were able to make changes to our prototype. We then repeated the process of constructing, presenting and testing and a new prototype in the following weeks.

Solutions Considered from new feedback

Some solutions that were considered from our volunteers included, adjusting the handle position, adding different triggers throughout the PVC pipe for different launch distances, needing a stronger mechanism to power the launcher and different grips to help users hold the product.

Description of Final Approach and Design

The final design of the Rod Squad Launcher incorporates a device that is detachable from the user's fishing rod while also being user-friendly. The device consists of PVC pipe as the framework for the launcher (see Appendix F, Figure 1). The fisher puts the bait on their Hide-a-Hook bobber and inserts the bobber inside the tube (see Appendix F, Figure 2 for bobbers). This tube consists of 1-1/2in schedule 40 PVC pipe with two slits, cut using a CNC router, on opposite sides of the tube. One slit extends to the end of the tube and has a widened opening to allow the fishing line to travel with the bobber (see Appendix F, Figure 3 and 4). The other slit is closed at both ends. At the back end, the slit has a specialized mushroom design that locks the slingshot into the trigger and allows for the user to use either hand (see Appendix F, Figure 5). The other end of this slit extends all the way to the front end, stopping two inches short. This allows for the inner sled to be stopped while allowing the projectile, the bobber and bait, to travel out into the air.

Inside the PVC Pipe is the inner sled. It is made of solid PVC that was lathed down from a larger piece (see Appendix F, Figure 6). This solid sled allows for more weight and momentum for projection and a more secure attachment of the drawback handle. The drawback handle is made from a 1/4in-4in bolt with InstaMorph molded around it; this allows the handle to be tapped into the PVC sled for a secure connection and also allows the handle to be morphed to include a groove to hold the slingshot band in place (see Appendix F, Figure 7). The slingshot band is anchored at the front end via an eye hook bolt tapped into a PVC coupling that was cemented onto the pipe's end (see Appendix F, Figure 8).

The device is attached to the fishing rod via the handle. The handle is wrapped in Dycem with large fishing rod clips overtop to keep from rotating (see Appendix F, Figure 9). A 1-1/4in PVC tee joint is snugly slid overtop the clips. A 1-1/2in PVC adapter is used to join the tee joint to a 90-degree PVC elbow. These three joints are cemented together (see Appendix F, Figure 10). The launcher fits into the elbow and is able to be used with or without the fishing rod (as seen in Figure 1 above).

Outcome:

Throughout our design process, user feedback was crucial. Initially, only virtual feedback was available with end users. Functional testing of some of our original user needs were done by members of the group, this included projection distance, weight and length of device. However, ease of use was one of the most important needs so in-person testing was essential for this project. Once a prototype was ready and had completed the objective functional testing, meetings were set up with local volunteers who were interested in the device as our primary user, Kim Heim, was unavailable.

During in-person testing, the usability was measured with think/talk aloud from the volunteers. Each part of the device was discussed from the first steps of set up to the launching of the bobber. Usability was also measured with an SUS Survey for an objective measure (see Appendix G for results). To encourage honest feedback, this survey was emailed to the participant after the testing so they could complete it without a member of the Rod Squad present.

From the functional testing, our device projected an average of 28ft, weighed 2.95lbs, and was 24in long. This met our physical goals for weight and length however it was just short of our goal for projection distance. Shortening of the slingshot band has proven to increase the projectile distance. We are confident that by the project, the goal can be reached.

Since our design competition is part of a design course, we have one more design iteration until the final product is given to the fishing program. We plan to continue to improve our device in these areas to get the best product for the Gone Fishin' program. Therefore, the most recent user testing feedback, which mostly consisted of usability criticism, will be incorporated then. There were three main points on the usability: pull back of slingshot, handles, and attachment directly to the wheelchair.

Our volunteers struggled to pull back the handle to the locking "mushroom" trigger; this was a design concern from the beginning. In order to launch to meet our goal, the device would require lots of force to power. Other user feedback was placement of handles. The original design had no handles; this caused major slippage and an inability to use the launcher. An additional handle was in an earlier design iteration, but the placement was not optimal. Lastly, attaching the device directly to the user's wheelchair was suggested by one of our users.

Further design iterations would include using a pully system or even an additional detached reel with stronger string to pull back the inner sled, adding the second handle to the underside of the device at the half-way mark, and using a 45-degree elbow to attach the device to the user's seat plate.

Cost

The estimate for the total cost of the device is $50. The PVC is estimated around $15 for the fittings and tube. The slingshot band is estimated at $11 for a set of 4. This device requires a special hook and bobber combination in order to launch properly and accurately. The special hook and bobber combination is available commercially under the name "Hide-a-Hook". The "Hide-a-Hook" bobbers cost about $4 for a set of 3. The remaining items (hardware, InstaMorph, PVC cement, etc.) are estimated to be $20 total.

Significance

Our intent is to create a dependable and inexpensive adaptive fishing rod that is able to help patients with limited upper body mobility cast fishing lines as independently as possible. These patients will be from UPMC Mercy Inpatient Rehabilitation Hospital and will be casting off of the piers at PNC park. Independently casting legitimizes patient's independence and positively affects their disposition.

It is important to empower and restore the self-confidence of patients with limited upper body mobility. The program "Gone Fishin'" at UPMC Mercy Rehabilitation Center takes patients from the in-patient recovery wing on a recreational daytrip to go fishing at PNC Park in Pittsburgh. This is a great start for many patients. After a traumatic incident resulting in new injuries and lessened physical abilities, many patients become scared and insecure in themselves. A common worry among patients is about getting back out into the community and trying to navigate that. This program does a good job of integrating patients back into the community. Our device will allow patients to have even more of their independence back and will improve their outlook on life. It is important that patients realize that adaptive equipment is out there and that they are capable of much more than they originally think.

Our device is one of a kind. Currently, there is not much on the market for adaptive casting. There are many adaptive fishing rods available commercially but almost nothing that promises the ability to cast the fishing line. Many adaptive devices available commercially must also be adapted further after purchase. Our device is the only one that has a universal attachment for any fishing rod and also promises the ability to cast out.

Appendix A

Figure 1 - Example of adaptive fishing rod equipped with button power to auto reel in the line.4

Appendix B

Figure 2 - Experience Map developed by Rod Squad.

Appendix C

Figure 3 - Benchmarked Concept Matrix

Appendix D

Figure 4- Benchmarking of Current Solutions researched.

Appendix E

Figure 5 - Specifications and testing on Slingshot Design.

Appendix F

Figure 1 – PVC pipe as framework

Figure 1 – PVC pipe as framework

Figure 2 – Hide-a-Hook bobbers used

Figure 3– Closed on one end, open at front end that leads to widened opening (see figure 5)

Figure 4 – widened opening with PVC Coupling cemented on firing end.

Figure 4 – widened opening with PVC Coupling cemented on firing end.

Figure 5 – Mushroom trigger at the end of the closed slit.

Figure 6 – Solid PVC sled with threaded hole in center.

Figure 7 – InstaMorph handle around hex bolt.

Figure 8 – Slingshot band tied around eye hook bolt; the other end of slingshot band is attached to InstaMorph handle.

Figure 9 – Fishing rod handle wrapped in Dycem with fishing rod clips around.

Figure 10 – PVC joints (tee, adapter and 90-degree elbow) cemented together.

Appendix G

| User | SUS Score – attached to fishing rod | SUS Score – un-attached from fishing rod |

|---|---|---|

| User 1 | 75 | n/a |

| User 2 | 70 | 87.5 |

| User 3 | 57.5 | 72.5 |

| User 4 | 80 | 95 |

| User 5 | 77.5 | 70 |

References

- AssistiveTechnology Industry Association. What is AT?. https://www.atia.org/home/at-resources/what-is-at/ November 18, 2020

- National Council for Therapeutic Recreation Certification. About Recreational Therapy. https://www.nctrc.org/about-ncrtc/about-recreational-therapy/ November 18, 2020

- The UPMC Rehabilitation Institute. On Summertime Fishing Trips, One Physical Therapist Inspires Hope. UPMC Health Beat. https://share.upmc.com/2018/08/life-changer-charlene-subrick/ November 18, 2020.

- Fishing Abilities,Inc. Freedom Fishr Power-Assist Reel System. http://www.fishingabilities.com/reel.html November 18, 2020

Acknowledgements

The Rod Squad would like to acknowledge the efforts of our professors, Dr. Mary Goldberg, Dr. Anand Mhatre, Dr. Jonathan Pearlman as well as the teaching assistant, Stephanie Vasquez Gabela. Additional thanks go to Charlene Subrick and Cat Samsa for their organization of the fishing program and advice throughout the design process. Moreover, special thanks to Kim Heim, our primary user, for her feedback throughout the process. Additional thanks to our testing volunteers for bringing user perspective and willingness to test our device in the future.