Evaluation of the Durability of Selected Pushrim-Activated Power-Assist Wheelchair Using the ANSI/RESNA Standards

Hsin-yi Liu, BS, Rory A. Cooper, PhD, Shirley G. Fitzgerald, PhD, Samuel Connor, BS

Department of Rehabilitation Science and Technology, University of Pittsburgh

Human Engineering Research Laboratories, VA Pittsburgh Healthcare System, Pittsburgh PA

Abstract:

The population of PAPAW is still growing because its advantage of improving propulsion efficiency. This paper compared the durability of PAPAWs of three models: Xtender, I-Glide (Johnson & Johnson), and E-motion (Alber). There were three wheelchairs for each model in this paper, and all the PAPAWs were tested by the fatigue tests according to the ANSI/RRESNA Wheelchair Standards. Xtender had the most equivalent cycles and most cost-effectiveness, whereas E-motion had the least equivalent cycles and also was the least cost-effective model.

Key words:

pushrim-activated power-assist, wheelchair, fatigue test

Introduction:

The pushrim-activated power-assist wheelchair (PAPAW) is a hybrid wheelchair between powered and manual wheelchairs. When the user applies a torque on the pushrim, the PAPAW generates a force proportional to the torque contributed by the user. The power exerted by users is decreased, and the range of motion of upper extremities needed to propel is significantly smaller when operating PAPAWs[1, 2]. These research results imply that using a PAPAW is a possible way to reserve wheelchair users’ energy in daily life and to avoid injury due to propelling a manual wheelchair. Although PAPAWs have such advantages, information about its durability and utility are still not clear.

Wheelchair standard testing following American National Standards Institute (ANSI) and Rehabilitation Engineering and Assistive Technology Society of North America (RESNA) requirements are used by the U.S. Food and Drug Administration for giving approval. The standard test results serve as a baseline for purchasers, clinicians, and users when comparing products. Among the standard tests, the fatigue tests, including double-drum test and curb-drop test, simulate three to five years of use. If the wheelchair passes the double-drum test, it goes on to curb-drop test. The total cycles completed in the fatigue tests are an indicator of the durability.

Comparing the results of fatigue testing among depot, lightweight, and ultralight wheelchairs[3-5], most of the depot and lightweight wheelchairs failed prematurely, but only 1 of 12 ultralight wheelchairs failed during testing. The testing results of the powered wheelchairs had a similar phenomenon. The equivalent cycles of K0011 and K0014 wheelchairs are significantly greater the K0010 non-programmable powered wheelchairs[6, 7]. The data is more meaningful to the end users and purchasers when discussing cost-effectiveness (cost-effectiveness is defined as the cycles until failure divided by the purchase price). From the studies cited above[3-7], the ultralight wheelchairs is much more cost-effective than the lightweight and depot wheelchair, but the higher classified powered wheelchair is not necessarily more cost-effective than the low-cost non-programmable powered wheelchair[7]. This information would influence the method of reimbursing wheelchairs in insurance.

There is only one report about the durability of the PAPAWs[8]. There were two PAPAWs of the same model and they both passed the fatigue tests. This report addresses the fatigue test results for 3 different models, 9 PAPAWs in total, and provides a general view of the reliability of PAPAWs.

Research Question:

- What is the occurrence of failure in PAPAWs during ANSI/RESNA fatigue tests?

- How do the results of fatigue tests of PAPAWs compare to other type of wheelchairs?

- Which PAPAW model is most cost-effective[4]?

The failure in this report indicates permanent structural damage or repairs that would immobilize the wheelchair, such as the frame, axel, and caster stem breaking.

Methods:

The fatigue tests were conducted according to the ANSI/RESNA Wheelchair Standards[9]. When permanent failure occurred, the testing came was concluded. For the purposes of comparison to fatigue life, the following formula was used to compute the equivalent number of cycles:

Total Cycles = ( Double-Drum Tester Cycles) + 30( Curb-Drop Tester Cycles) (1)

The cost of each wheelchair (per unit) was: $8,489 (I-Glide), $3,684 (Xtender), and $3,968 (E-motion wheels and Quickie2 frame). The purchase price normalized by the total equivalent cycles is the cost-effectiveness of the wheelchair (cycle/$).

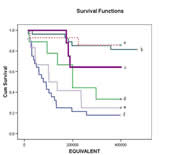

Descriptive statistics (means and standard deviations) were computed for total cycles and cost effectiveness. PAPAWs were compared to other wheelchair types (depot, lightweight, ultra-lightweight, minimal adjustable power, fully adjustable power) with respect to durability. Total cycle numbers were compared using a survival curve, with different wheelchair types being compared.

Results:

The fatigue tests stopped when permanent failure occurred or the wheelchair completed 200,000 cycles in double-drum test and 6,666 cycles in curb-drop test. The results of completed cycles are shown in Table 1. I-Glide-2 had permanent damage in double-drum test because of the testing equipment failure, so that its data was discarded from analysis. The average equivalent cycles of all PAPAWs are 318,292 ± 112,776.6 cycles (N=8). All the Xtender and I-Glide PAPAWs passed the fatigue tests and had the equivalent cycles of 399,980, whereas the E-motion had a lower number of average equivalent cycles (182,145). The cause of the failure for all E-motion PAPAWs was spokes collapsing (figure 1), and they did not survive the double-drum test. Figure 2 compares the survival rate of PAPAWs with other types of wheelchairs. The survival rate of the PAPAWs (62.5%) during the first 400,000 cycles is between K0011 and K0014 powered wheelchairs (80%) and lightweight manual wheelchairs (29%). “Steps” in the survival curve indicate the occurrence of the permanent failure. There are three steps near to 200,000 cycles due to the failure of E-motion, and then the survival curve becomes straight until 400,000 cycles. This means that E-motion PAPAWs had similar durability. The cost-effectiveness of PAPAWs is shown in Table 2. The Xtender was the most cost-effective model. Although the average equivalent cycles of I-Glide were much more than E-motion, E-motion was as cost-effective as I-Glide because the cost of I-Glide was twice more than twice that of the E-motion.

| Model | Double Drum | Curb Drop | Total Cycles | Average of total cycles |

|---|---|---|---|---|

I-Glide 1 |

200000 |

6666 |

399980 |

|

I-Glide 2 |

NA |

NA |

NA |

399980 |

I-Glide 3 |

200000 |

6666 |

399980 |

|

Xtender 1 |

200000 |

6666 |

399980 |

|

Xtender 2 |

200000 |

6666 |

399980 |

399980 |

Xtender 3 |

200000 |

6666 |

399980 |

|

E-motion 1 |

182633 |

0 |

182633 |

|

E-motion 2 |

176551 |

0 |

176551 |

182145.3 |

E-motion 3 |

187252 |

0 |

187252 |

|

Mean |

318292 |

|||

SD |

112776.6 |

| Model | cost-effective (cycles/$) |

|---|---|

| I-Glide | 47.11 |

| Xtender | 108.56 |

| E-motion | 45.9 |

| Mean | 63.46 |

| SD | 35.83 |

Discussion:

The configurations of the three models are different. The motor and battery systems of I-glide are under the seat. For the Xtender, the motor system is in the hub of the wheel with three additional supportive spokes to stabilize the hub, and the battery system is behind the backrest. E-motion has the advantage that if can retrofit to most kinds of frames. The motor and battery systems are both in the hub of the wheel with regular spokes. The different locations of the motor and battery systems influence the weight distribution of the wheelchair, and consequently induce different impact profiles during the fatigue tests. All the E-motion PAPAWs failed around the same number of equivalent cycles (182,633, 176,551, and 187,252 cycles respectively) due to spokes bending and breaking. The advantage of easily changing the wheels between manual and power-assisted mode is quite convenient for wheelchair users, but the heavy power-assist wheels (weight almost 50 lbs for each) and fragile spoke system impedes the intended advantage of the E-motion. The performances of PAPAWs in fatigue testing were quite distinct among the three models, but are consistent within the same model. The durability of PAPAW varied according to model. By assuming that 400,000 equivalent cycles is and estimated 3 to 5 years of typical wheelchair users, we can get an estimated life of a wheelchair. E-motion had an estimated life of 1.3-2.3 years, whereas I-Glide and Xtender had more than 3-5 years.

Acknowledgement:

The authors thank for the help and generosity from all faculties, staffs, and colleagues in the Human Engineering Research Laboratories. This research was supported by VA-RR&D grant # B3142C.

Reference:

- Arva, J., et al., Mechanical efficiency and user power requirement with a pushrim activated power assisted wheelchair. Medical Engineering & Physics, 2001. 23(10): p. 699-705.

- Corfman, T.A., et al., Range of motion and stroke frequency differences between manual wheelchair propulsion and pushrim-activated power-assisted wheelchair propulsion. Journal of Spinal Cord Medicine, 2003. 26(2): p. 135-40.

- Cooper, R.A., et al., Evaluation of selected ultralight manual wheelchairs using ANSI/RESNA standards. Archives of Physical Medicine & Rehabilitation, 1999. 80(4): p. 462-7.

- Cooper, R.A., et al., Performance of selected lightweight wheelchairs on ANSI/RESNA tests. American National Standards Institute-Rehabilitation Engineering and Assistive Technology Society of North America. Archives of Physical Medicine & Rehabilitation, 1997. 78(10): p. 1138-44.

- Cooper, R.A., et al., Life-cycle analysis of depot versus rehabilitation manual wheelchairs. Journal of Rehabilitation Research & Development, 1996. 33(1): p. 45-55.

- Fass, M.V., et al., Durability, value, and reliability of selected electric powered wheelchairs. Archives of Physical Medicine & Rehabilitation, 2004. 85(5): p. 805-14.

- Pearlman, J.L., et al., Evaluation of the safety and durability of low-cost nonprogrammable electric powered wheelchairs. Archives of Physical Medicine & Rehabilitation, 2005. 86(12): p. 2361-70.

- Cooper, R.A., et al., Evaluation of a pushrim-activated, power-assisted wheelchair. Archives of Physical Medicine & Rehabilitation, 2001. 82(5): p. 702-8.

- Institute, A.N.S., American national standard for wheelchairs. 1998, New York: American National Standards Institute

Highlights

- Source Ordered

- No Tables

- Very Compatible

Gargoyles

Disney produced a television show in the mid 1990s called Gargoyles. It's a great show and I'm a big fan. A few years ago Disney started to release the show on DVD. The last release was of season 2, volume 1. That was two years ago. Volume 2 has not been released. Why? Poor sales. So if you should find yourself wanting to support my work, instead I ask you pick up a copy of season 2, volume 1. It's a great show and you might find yourself enjoying it.